In today’s era of rapid renewable energy expansion, the role of digitalization in solar energy management cannot be overstated. Solar power plants are no longer just arrays of photovoltaic panels quietly producing electricity; they’ve evolved into intelligent, data-driven systems capable of self-diagnosis, optimization, and predictive maintenance.

At the heart of this transformation lies SCADA — Supervisory Control and Data Acquisition. SCADA systems act as the central nervous system of a solar power plant, providing real-time visibility, control, and analytics across every component, from individual inverters and combiner boxes to grid interconnections.

Table of Contents

Whether it’s a 100 kW rooftop installation or a 100 MW solar park, Supervisory Control and Data Acquisition ensures that plant operators can monitor performance, prevent losses, and enhance energy yield efficiently. This blog explores in detail how SCADA empowers solar power plants, its architecture, working principles, benefits, challenges, and emerging trends shaping the future of digital solar management.

What is SCADA?

SCADA (supervisory control and data acquisition) is an essential integrated software-hardware system in solar plants that oversees the entire solar power generation process, starting from sunlight capture in panels to electricity export into the grid. It connects various field devices, collects operational data, and visually presents this information on user-friendly dashboards. SCADA systems also facilitate remote control actions, allowing operators to restart inverters or perform switch operations when necessary.

Designed for grid-connected and large-scale solar installations, SCADA continuously gathers data from modules, inverters, sensors, and meters, transmitting it to a control center or cloud platform for real-time monitoring and control. This capability is crucial for managing multiple devices across extensive areas. As a category of industrial control systems (ICS), Supervisory Control and Data Acquisition not only monitors and supervises processes but also supports data-driven decision-making. The graphical user interface (GUI) provided by Supervisory Control and Data Acquisition tools enables the management of various industrial processes, classifying Supervisory Control and Data Acquisition and ICS under the broader operational technology (OT) category.

Key Functions in a Solar Plant

A Supervisory Control and Data Acquisition system in a solar plant typically performs the following:

- Data acquisition & monitoring: Tracks generation data including voltage, current, power output, and energy yield from inverters, strings, or modules. It captures real-time operational parameters such as AC/DC power output, module string currents, voltages, ambient temperature, irradiation, inverter status, and grid export.

- Remote supervision and control: Operators can remotely monitor and control plant equipment, such as inverters, breakers, and trackers, allowing them to execute commands without the need for on-site manual checks.

- Fault detection and alarm management: The system is designed to send immediate alerts when faults arise, such as inverter failures, low performance levels, or string disconnections. It effectively identifies underperformance and equipment faults, as well as deviations from expected operational values, allowing for timely maintenance actions through its alert mechanism.

- Data Logging and Analysis: Stores operational data to facilitate performance analysis, trend evaluation, and reporting. It enables tracking of trends and benchmarking of performance metrics such as Performance Ratio and Capacity Utilization, contributing to the optimization of plant operations through comprehensive data storage and analysis over time.

- Grid-code compliance & integration: In large solar plants, Supervisory Control and Data Acquisition may interface with grid dispatch/control systems, managing set-points for active/reactive power, curtailment and other grid-integration functions.

Why SCADA is Crucial for Solar Plants

In modern solar power generation, Supervisory Control and Data Acquisition has become an indispensable tool for ensuring efficiency, reliability, and profitability. As solar plants grow in scale and complexity, manual monitoring is no longer enough — you need an intelligent system that can see everything, analyze everything, and act instantly. That’s where SCADA comes in.

1. Real-Time Monitoring for Maximum Uptime

Solar plants utilize extensive arrays of modules and inverters, necessitating a dedicated Supervisory Control and Data Acquisition system for real-time monitoring. This system collects output data from each module string and inverter, uploading alerts for any faults, performance dips, or alarms instantly. The critical nature of this visibility ensures that potential issues can be managed proactively, preventing undetected faults that might result in energy loss or increased operational costs. SCADA continuously tracks vital parameters, including voltage, current, irradiance, inverter status, and energy output, enabling operators to detect faults immediately and maintain optimal power generation despite fluctuating weather conditions. For instance, if one of fifty inverters fails, SCADA promptly notifies technicians, allowing for swift intervention to mitigate significant energy losses.

2. Enhanced Operational Efficiency

Large-scale solar installations, often located in remote areas, benefit from SCADA (Supervisory Control and Data Acquisition) systems, which enable centralized control of operations. This technology allows for remote commands to inverters, breakers, and trackers, minimizing the need for on-site manual intervention. By automating control logic, Supervisory Control and Data Acquisition reduces human error and enhances operational efficiency, allowing multiple sites to be monitored from a single control center. This leads to lower operational and maintenance (O&M) costs and higher uptime, which are critical for investors and asset owners. Additionally, SCADA provides a unified interface for managing various interconnected systems, such as inverters and weather sensors, facilitating more effective oversight and reducing the requirement for on-site supervision.

3. Fault Detection and Predictive Maintenance

SCADA adoption in solar plants is primarily driven by the need to reduce downtime and performance losses. It detects abnormalities early, allowing for immediate alerts and action. By analyzing historical data trends, SCADA facilitates a shift from reactive repairs to predictive maintenance, resulting in fewer lost generation hours, improved yield, and enhanced ROI. Additionally, SCADA addresses challenges in identifying hidden inefficiencies such as soiling losses and shading effects, enabling early detection of equipment anomalies, predicting component failures, and scheduling preventive maintenance, all of which contribute to improved plant availability and extended asset life.

4. Data-Driven Decision Making

SCADA transforms data into actionable insights for optimizing solar performance by analyzing Performance Ratio (PR), capacity utilization, and specific yield against irradiance. It facilitates benchmarking across different plant types, aids in planning operations and maintenance (O&M) schedules, and supports strategic decisions on upgrades and replacements of equipment. This data intelligence is crucial for manufacturers and EPCs to maximize asset value, allowing plant owners to make informed decisions over time. SCADA provides historical performance comparisons and KPIs such as PR and Capacity Utilization Factor (CUF) to drive strategic improvements.

5. Grid Integration and Regulatory Compliance

Supervisory Control and Data Acquisition systems are crucial for utility-scale and large C&I solar plant projects, enabling management of active/reactive power set-points, grid curtailment commands, and ensuring compliance with grid-code requirements. They enhance operational reliability and safety through event logging, documentation for warranty claims, and cybersecurity measures. SCADA allows for seamless integration with regional control centers by facilitating remote curtailment commands and providing real-time data, ensuring stable, safe, and compliant plant operation while enhancing grid reliability.

6. Centralized Control of Multi-Site Operations

Companies with manufacturing units are increasingly installing solar systems across various setups, utilizing Supervisory Control and Data Acquisition for centralized monitoring and control. SCADA allows for expansion through plug-in capabilities, ensuring consistent KPIs and dashboards across different asset classes, which is crucial when managing large portfolios. For those overseeing multiple solar assets, SCADA facilitates performance comparison, benchmarking, and efficient maintenance planning. This centralized approach shifts operations from reactive management to smart, data-driven supervision.

7. Cost Efficiency and ROI Optimization

Supervisory Control and Data Acquisition systems enhance profitability for industrial decision-makers by increasing energy yield, lowering operational costs, extending asset life, and improving investment cases through better risk assessments. Despite the initial investment, Supervisory Control and Data Acquisition offers rapid payback by reducing manual inspections, minimizing downtime, and facilitating quicker fault responses, ultimately maximizing project profitability through improved generation efficiency and reduced overheads.

Architecture of a Solar Supervisory Control and Data Acquisition System

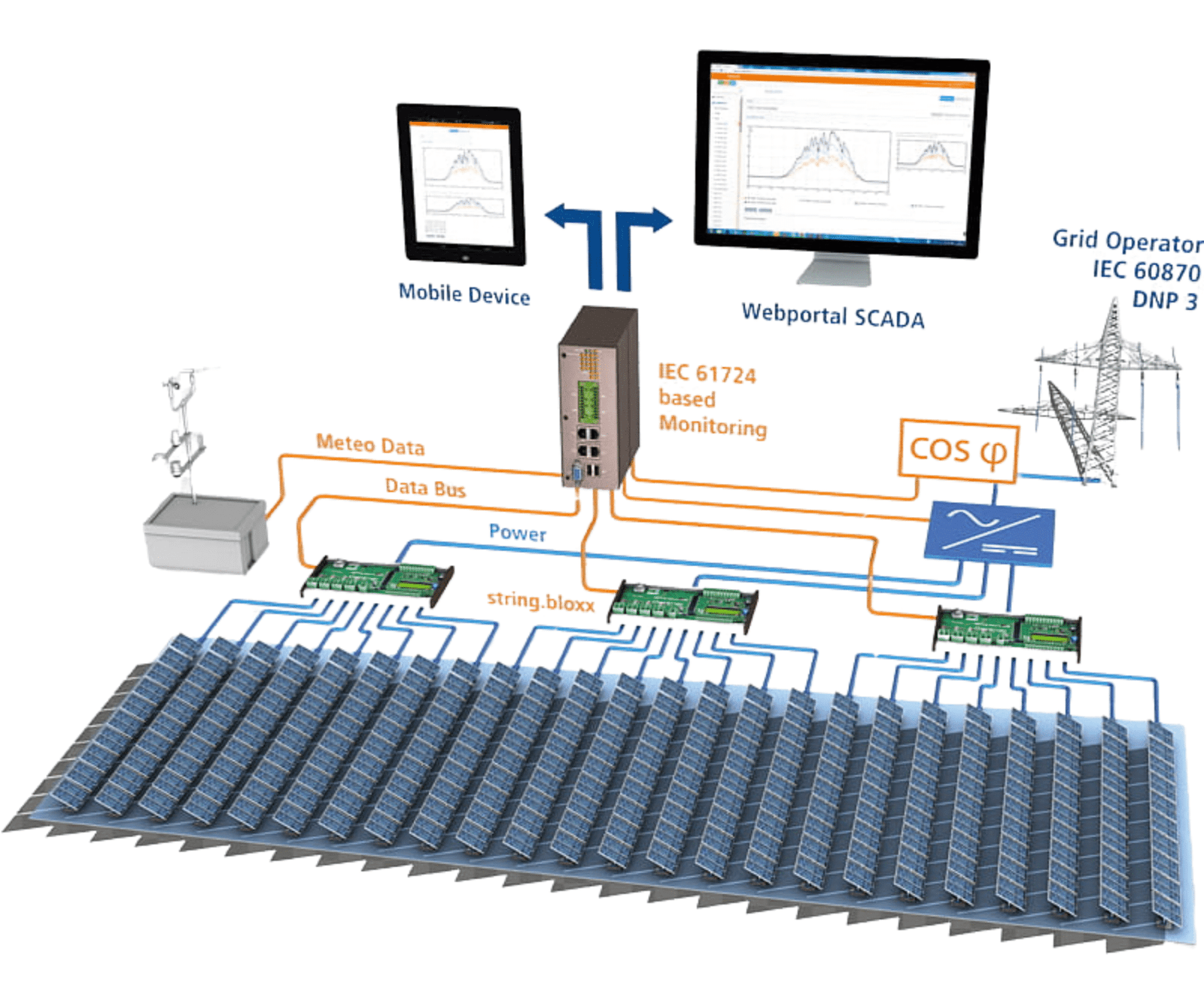

A Supervisory Control and Data Acquisition system in a solar power plant is typically structured in three layers — field devices, communication infrastructure, and supervisory software.

A. Field Layer – Data Collection Devices

This document outlines the foundational elements of a solar power system’s Field Layer, which includes essential physical devices such as solar arrays, inverters, monitoring systems, auxiliary components, environmental sensors, meters, and grid interface devices. Key functions involve operational data communication (voltage, current, power statuses) and control signal reception for system management. The Field Layer enables detailed monitoring of individual components like strings and inverters, facilitating quick performance assessments. Devices such as sensors, smart meters, weather stations, and data loggers play a critical role in measuring, recording, and transmitting operational data for performance analysis.

B. Communication Layer – Data Transmission

Data captured in the field must be transmitted to a central system, highlighting the critical nature of the communication network. Key architectural considerations include Local Area Networks (LAN) connecting devices like RTUs, PLCs, and inverters, and Wide Area Networks (WAN) for remote monitoring and access. Security is vital, utilizing VPNs, firewalls, and redundant industrial switches. Established protocols and standards such as Modbus, IEC 61850, and DNP3 facilitate data transfer. Data concentrators manage multiple devices to communicate with SCADA servers. A robust communication infrastructure is essential for maintaining real-time visibility and control, particularly for large plants requiring high data volume and reliability.

C. Supervisory Layer – Control and Visualization

The architecture’s top layer comprises the software platform, which includes the SCADA server, Human Machine Interface (HMI), historian, control modules, analytics, and remote access. These components support real-time monitoring, historical data storage, performance tracking, and fault diagnostics. Key design considerations for the SCADA system include scalability to manage extensive I/O points, redundancy for high availability, vendor-independence for hardware compatibility, and robust security measures. The platform offers a user interface featuring dashboards, alarm systems, analytical tools, and remote control capabilities, enabling operators to manage and visualize plant operations efficiently.

How SCADA Works in a Solar Power Plant

1. Data Acquisition at the Field Layer

At the solar plant, a multitude of devices continuously generate raw data vital for subsequent operations such as monitoring and analytics. Key activities include sensors recording environmental conditions (irradiance, temperatures, wind speed) and string-monitoring boxes (SMBs) measuring string voltages and currents. Inverters report AC/DC parameters, while energy meters and switchgear provide data to the system. Remote Terminal Units (RTUs) and PLCs aggregate local data for further analysis. SCADA systems collect inputs from PV modules, inverters, weather sensors, and energy meters, with the objective of capturing accurate, real-time data from each device in the solar field.

2. Communication & Data Transmission Layer

Data collected in SCADA systems must be efficiently and securely transmitted through the communication network layer. Data transfer occurs via fiber optic cables for high-speed transmission, Ethernet or wireless connections for smaller setups, and communication protocols such as Modbus RTU/TCP, IEC 60870, IEC 61850, or DNP3. This network serves as a link between physical hardware and control software, ensuring a seamless data flow. Advanced SCADA systems enhance security through encrypted VPNs, redundant network paths, and real-time backups. Reliable transmission requires compatible protocols, a suitable network infrastructure (LAN, WAN, fiber optics, Ethernet, wireless), and gateways/data concentrators for stream forwarding. Key considerations include latency and reliability, security for remote access, and scalability for extensive data points in large installations.

3. Supervisory & Control Layer (Processing, HMI, Analytics)

All processed data is displayed on an intuitive HMI dashboard for both desktop and mobile access. Operators can monitor live energy generation metrics, weather effects on performance, alarms for faults, and historical trends. The HMI enables remote control of devices such as inverters and alarm resetting. At the system’s core, the SCADA server manages data processing, analytics, and control logic. HMI dashboards showcase live KPIs and allow for control commands. Additionally, analytics facilitate trend charts and performance benchmarking, turning raw data into actionable insight to enhance operational excellence.

4. Data Flow: From Sensor to Decision

SCADA enhances monitoring by learning from data, generating reports on daily/monthly energy yield, performance ratio, specific yield, inverter-wise performance, and grid compliance. These insights assist O&M teams and plant owners in identifying underperforming assets and planning maintenance or expansions. The system involves field devices measuring parameters, RTUs/PLCs aggregating data, and communication networks transmitting this data to the SCADA server, which processes and acts on it while providing operators with dashboards and alerts. Historical data is preserved for performance reviews and predictive maintenance.

Importance of SCADA in Solar Energy Management

1. Real-Time Visibility & Performance Monitoring

A solar plant’s performance is subject to minute-by-minute fluctuations due to various factors, and SCADA (Supervisory Control and Data Acquisition) facilitates real-time monitoring of the plant’s components, enabling operators to assess efficiency. Key benefits of SCADA include live tracking of power generation, early detection of underperforming equipment, and rapid resolution of issues, promoting proactive management rather than reactive troubleshooting. SCADA provides critical data on generation, device status, environmental conditions, and grid interaction, allowing for immediate identification of performance deviations and shifting operations from a reactive to a proactive approach.

2. Data-Driven Decision Making & Optimization

Solar plants generate significant operational data, which can become unusable without a SCADA system. A well-executed SCADA system collects and analyzes this data, allowing for the identification of performance issues, module degradation rates, and optimized maintenance schedules. It provides insights into KPIs such as Performance Ratio and specific yield, helping operators recognize patterns of inefficiency. SCADA facilitates informed decision-making for upgrades and maintenance, supporting continuous improvement and enhancing energy yield per installed kW.

3. Remote & Multi-Site Management

Modern solar portfolios utilize SCADA for centralized, remote management across multiple states or countries. This system allows operators to monitor performance 24/7 via dashboards, initiate actions like starting or stopping inverters, and implement grid commands from anywhere, significantly reducing the need for site visits. SCADA provides a comprehensive operational view for EPCs and asset owners managing various installations, enabling efficient monitoring and benchmarking across sites. As portfolios grow, SCADA serves as a vital networking and control backbone, supporting the management of large-scale and international solar assets.

4. Grid Integration, Compliance & Asset Security

In large-scale solar plants, SCADA systems are essential for maintaining grid stability and adhering to utility regulations. They manage active/reactive power and voltage settings, execute curtailment commands from grid operators, and log power quality metrics. This functionality ensures efficient power delivery while complying with grid codes and performance standards. SCADA also provides real-time measurements of grid export and supports regulatory audits, enhancing transparency and performance verification. Additionally, remote monitoring and alarms improve operational security and reliability, which is vital for manufacturing units or industrial investors concerned with operational risk management.

5. Cost Efficiency & Return on Investment

SCADA automates report generation for regulatory bodies and investors, providing daily/monthly summaries, performance tracking, and maintenance logs, which enhances transparency and operational credibility. It aids in identifying energy losses and ROI opportunities while saving significant data compilation time. SCADA contributes to cost savings and yield improvements by reducing operational costs, increasing energy yields, extending asset life through early degradation detection, and minimizing unexpected downtimes. This capability is crucial for decision-makers in manufacturing and EPC sectors, ensuring an edge in a competitive market.

Key Features of an Advanced Solar SCADA System

- Real-Time Monitoring & Data Acquisition: Continuous operational parameters, including voltage, current, power output, irradiance, and temperature, are collected from inverters, string boxes, sensors, and weather stations. This process includes high-frequency data sampling, achieving detailed performance visibility with intervals as short as seconds.

- Remote Control & Supervisory Capabilities: Operators have the capability to remotely start and stop inverters, switch breakers, and adjust set-points. Additionally, there is support for control logic (PPC) that enforces both active and reactive power set-points, as well as commands based on grid requirements.

- Alarm Management and Fault Detection: Real-time alerting facilitates immediate awareness of anomalies, faults, or abnormal deviations such as inverter faults and string underperformance. The system offers configurable notification channels, including email and SMS, to inform users of critical events. Additionally, it ensures comprehensive logging of events and alarms, which supports effective diagnostics.

- Historical Data Storage & Analytics: Long-term data archiving is essential for utilizing historical information through a historian to enable trend analysis focused on performance metrics such as Performance Ratio, inverter health, and yield forecasting. Comprehensive reporting tools facilitate the generation of daily, monthly, and yearly performance summaries, providing insights into operational efficiency. Additionally, advanced analytics play a critical role in optimizing operations, allowing for enhanced energy yield and informed maintenance planning, ultimately leading to more efficient management of resources and improved overall system performance.

- Grid Compliance & Active / Reactive Power Control: Support for grid-code compliance is facilitated through defined set-points for both active and reactive power. Additionally, a modular architecture is proposed to effectively integrate a Power Plant Controller (PPC), enhancing interactions with the grid for improved operational efficiency and adaptability.

- Flexible, Vendor-Independent Architecture: Compatibility with various inverter brands, string boxes, and meters is ensured through standard protocols. This system supports multiple communication protocols including Modbus, IEC-61850, IEC-60870, DNP3, and OPC, facilitating interconnectivity. Additionally, its scalable and modular design allows for future expansion accommodating more inverters, storage, and distributed assets.

- High Reliability & Redundancy: Local and remote server redundancy is implemented to guarantee high availability of services. Additionally, comprehensive diagnostics are conducted to facilitate troubleshooting and sustain overall system health.

Challenges in Implementing SCADA Systems

- High Initial Cost: Implementing SCADA (Supervisory Control and Data Acquisition) systems involves a range of essential components, including servers, networking hardware, PLCs (Programmable Logic Controllers)/RTUs (Remote Terminal Units), licenses, cybersecurity systems, and skilled engineering teams. A notable challenge in this deployment is the high capital expenditure (capex) required and the complexity involved, especially for remote or large-scale solar farms. The investment encompasses substantial costs for RTUs, PLCs, servers, communication hardware, and software. For smaller or distributed solar plants, justifying this investment can be particularly challenging without a clear return on investment (ROI).

- Communication and Network Reliability: Remote solar sites encounter significant challenges due to poor connectivity, which results in data latency and packet loss, ultimately impacting real-time monitoring capabilities. Communication failures between field devices and the SCADA server can create data gaps, undermining trust in the integrity of the monitoring system. Moreover, the infrastructure is often subjected to severe environmental conditions such as heat, lightning, and temperature fluctuations, complicating reliable networking efforts. The expansive geographical distribution of solar plants further exacerbates connectivity issues, with unstable fiber networks, RF interference, and substandard cabling contributing to data loss. A primary challenge remains the assurance of reliable, high-speed data transmission throughout the site.

- Cybersecurity Risks: SCADA networks face significant vulnerabilities, including unauthorized access, malware attacks, and remote hacking attempts. As these systems connect field devices to central servers, any security breach can lead to disruptions in plant operations. The primary challenge lies in implementing strong cybersecurity measures to protect critical infrastructure, which is frequently targeted due to its importance. Many SCADA systems utilize legacy communication protocols that may not offer sufficient encryption or authentication, leaving data exposed. To ensure robust security, it is essential to maintain continuous updates, secure architectural design, and enforce role-based access controls.

- Data Overload & Management: Solar plants produce extensive data every minute, including measures such as irradiance, temperature, string current, and inverter logs. The challenge lies in filtering through this data to extract useful insights while avoiding overwhelming noise. The SCADA systems within solar plants contribute significantly to this data volume, which encompasses weather conditions as well as string and inverter metrics. Effectively storing, processing, and analyzing this data in real time presents both technical and financial challenges. Therefore, a well-defined data strategy, incorporating edge storage, cloud solutions, and big data analytics, is essential for optimal management of solar plant data.

- Scalability Challenges: As plants expand or new devices such as trackers or battery systems are integrated, the Supervisory Control and Data Acquisition (SCADA) system must be capable of scaling efficiently without sacrificing performance. A primary challenge is to design an architecture that can accommodate future growth while preserving operational efficiency. As the plant increases its capacity—adding more inverters, strings, or locations—the SCADA system’s architecture must be adaptable. Failure to ensure flexibility in design can lead to significant costs when incorporating new devices or enhancing capacity.

- Lack of Skilled Workforce: SCADA (Supervisory Control and Data Acquisition) operation and maintenance demand a unique set of specialized skills, particularly in networking, automation systems, PLC (Programmable Logic Controller) and RTU (Remote Terminal Unit) programming, cybersecurity, and data analysis. A significant challenge faced in this field is the limited availability of trained professionals, especially for solar plants located in remote areas. The recruitment and retention of such specialized talent can prove difficult, complicating the effective operation and maintenance of SCADA systems in these locations.

Emerging Trends in SCADA and Digital Solarization

1. IoT-Enabled SCADA (IoT-SCADA)

IoT devices are enhancing SCADA systems by allowing them to capture more detailed performance data, such as module-level temperatures and string-level current, which improves situational awareness and facilitates quicker fault detection. The integration of IoT sensors throughout the plant for monitoring various parameters such as module temperatures and irradiance allows for significant reductions in the requirement for manual inspections. These sensors communicate through wireless networks (2G/3G/4G/5G) or MQTT to cloud platforms, which supports real-time remote monitoring, alerts, and analytics. This setup minimizes latency, reduces capital and operational expenditures (CAPEX/OPEX) by decreasing the need for extensive physical infrastructure, and enables easy scalability when expanding plant capacity.

2. Edge Computing & Distributed Intelligence

Edge computing significantly minimizes data transfer delays by enabling the processing of crucial information at the site of solar installations. This enhancement boosts responsiveness for vital operations such as inverter shutdowns, grid compliance, and disturbance management, thereby maintaining stability in high-capacity solar assets. The shift of SCADA computation to the “edge” — closer to field devices instead of relying on a central server — further reduces latency and enhances real-time decision-making capabilities while conserving bandwidth, which is essential for large and remote solar facilities. Additionally, edge nodes facilitate local execution of analytics, anomaly detection, and automated control logic, leading to improved system responsiveness.

3. AI / Machine Learning for Predictive & Adaptive Operations

SCADA platforms are integrating AI and machine learning to enhance predictive maintenance by analyzing historical and real-time data, enabling early detection of equipment failures and anomalies such as inverter degradation. This proactive approach reduces downtime and extends asset life. Advanced models utilize weather forecasts alongside performance data for dynamic optimization of inverter settings and battery dispatch. Anomaly detection algorithms facilitate root-cause diagnostics, providing insights into specific issues rather than just indicating a problem.

4. Digital Twins & Simulation-Based Modeling

Digital twins, defined as virtual replicas of solar plants, enable operators to simulate performance, test configurations, and forecast the impact of environmental changes on energy output. By integrating with SCADA systems, they transform raw data into practical operational insights. This technology facilitates the execution of “what-if” scenarios to evaluate operational changes prior to their physical implementation. Additionally, digital twins assist in predicting performance, planning maintenance activities, and evaluating the consequences of design modifications or new installations. Moreover, advanced frameworks leverage real-time data alongside simulations to continually refine predictive models, thereby enhancing their accuracy over time.

5. Cloud-Based Solar SCADA Systems

Cloud migration is a key trend in digital solarization, particularly with cloud SCADA systems. These systems enhance the management of multi-site portfolios by providing scalable storage and global access to critical insights, while reducing infrastructure costs and facilitating collaboration between remote and on-site teams. Cloud SCADA offers features such as remote dashboards, historical data storage, automated backups, and disaster recovery. Hybrid architectures combine on-premises and cloud solutions, addressing the need for real-time control alongside cost-effective analytics and long-term data retention.

6. Cybersecurity & Zero-Trust Models

Cybersecurity is increasingly vital for solar asset connectivity, with SCADA systems integrating encrypted protocols, multi-factor authentication, intrusion detection, and secure device provisioning to protect digital infrastructure. Vendors are adopting zero-trust architectures, role-based access, and encrypted communication methods. Research indicates that blockchain could enhance data integrity through tamper-proof logs for operations and maintenance. Additionally, AI-based threat detection is implemented for real-time monitoring and isolation of suspicious activities within SCADA networks.

SCADA and the Future of Smart Solar Operations

SCADA is evolving into the digital backbone of modern solar plants, moving beyond basic monitoring to enable intelligent and automated operations. Integrating IoT sensors and real-time analytics, SCADA enhances reliability and performance by providing detailed insights into system conditions. With edge computing, critical data is processed on-site for immediate responses, bolstering resilience. AI and predictive analytics allow SCADA systems to optimize performance and anticipate failures. Digital twin technology enables virtual simulations for operational evaluations.

Cloud-based platforms enhance management, offering remote accessibility and centralized analytics. Enhanced cybersecurity measures are essential for protecting SCADA systems as they coordinate interactions between energy storage and smart grids. Advanced technologies, such as AI-driven inspections and automated fault remediation, enhance efficiency and reliability, paving the way for smarter solar operations that maximize output and reduce costs.

Conclusion

SCADA has become far more than a monitoring tool—it’s now the digital engine that drives smarter, more resilient, and future-ready solar operations. As the industry moves toward higher capacities, hybrid systems, and grid-responsive energy models, SCADA’s role in ensuring intelligence, automation, and long-term performance has never been more crucial. From IoT integration and AI-driven analytics to digital twins, edge computing, and robust cybersecurity, SCADA empowers solar plants to operate with precision and predictability. The plants that invest in advanced SCADA systems today are the ones that will lead on efficiency, reliability, and scalability tomorrow.

In an increasingly competitive energy landscape, a smart SCADA-enabled solar plant is not just an operational advantage—it is a strategic necessity. Ready to elevate your solar plant operations with smarter, data-driven control systems? Explore how advanced SCADA architecture can transform your energy performance, improve reliability, and future-proof your assets. Stay informed, stay efficient—step into the future of intelligent solar operations today.

Frequently Asked Questions (FAQ)

1. What is SCADA in a solar power plant?

SCADA (Supervisory Control and Data Acquisition) is a digital system that monitors, controls, and analyzes the performance of a solar plant in real time. It collects data from inverters, meters, sensors, weather stations, and other critical equipment, helping operators ensure safe, efficient, and optimized plant performance.

2. Why is SCADA important for solar plant operations?

SCADA is essential because it provides real-time visibility, early fault detection, remote monitoring, automated reporting, and performance analytics. With SCADA, operators can minimize downtime, improve energy yield, enhance grid compliance, and reduce overall O&M costs.

3. How does SCADA work in solar power plants?

SCADA works by collecting data from field devices—such as sensors, inverters, combiner boxes, and weather stations—and transmitting it to a central control room. The system then processes and displays this data on user-friendly dashboards, allowing operators to make informed decisions or trigger automated actions to maintain plant performance.

4. What issues can SCADA detect in a solar plant?

SCADA can detect inverter faults, string underperformance, module temperature anomalies, cabling issues, grid disturbances, communication failures, and environmental deviations. Early detection allows for timely intervention and reduces production losses.

5. How does SCADA improve solar plant efficiency?

SCADA optimizes efficiency by continuously monitoring energy generation, identifying low-performing assets, highlighting operational bottlenecks, and enabling predictive maintenance. It ensures that the plant operates at maximum output with minimal downtime.

6. Is SCADA necessary for small or rooftop solar plants?

While small systems may use simpler monitoring tools, SCADA becomes highly valuable for commercial, industrial, utility-scale, and multi-site portfolios. It offers detailed analytics, automated reporting, and centralized management that smaller monitoring systems cannot provide.

7. Can SCADA integrate with battery energy storage systems (BESS)?

Yes. Modern SCADA systems integrate seamlessly with battery energy storage. They manage charging/discharging cycles, optimize energy flows, and support peak-load shaving, grid interactions, and backup functions—making hybrid solar plants more efficient and stable.

8. Is SCADA secure? How is data protected?

Advanced SCADA platforms include strong cybersecurity features such as encrypted communication, multi-factor authentication, firewalls, intrusion detection, and role-based access control. These layers help protect operational data and prevent unauthorized access.