As global industries accelerate toward energy independence, carbon neutrality, and long-term cost control, solar technology is evolving faster than ever. For industrial and commercial leaders, the conversation has shifted from “Should we go solar?” to “Which solar technology will future-proof our operations?”

Among the most promising advancements redefining solar performance is Heterojunction Technology (HJT)—a next-generation photovoltaic innovation that blends the best of crystalline silicon and thin-film technologies.

Table of Contents

This blog explores heterojunction solar technology in depth—how it works, why it matters, and how it is reshaping the economics of large-scale solar projects for manufacturing units, warehouses, logistics hubs, and industrial campuses.

What Is Heterojunction Technology?

A heterojunction is a junction formed between two distinct semiconductor materials, specifically amorphous silicon and crystalline silicon, which enables efficient separation and collection of charge carriers (electrons and holes) generated from sunlight. Heterojunction Technology (HJT) represents an advanced solar cell technology that integrates these two types of silicon, leading to enhanced efficiency, reduced losses, and improved long-term performance in comparison to traditional solar panels. HJT effectively combines the power generation capabilities of monocrystalline silicon with the passivation advantages of thin-film amorphous silicon, resulting in a highly efficient and stable solar cell architecture, particularly beneficial for industrial and commercial solar applications.

How Heterojunction Technology (HJT) Solar Cells Are Built

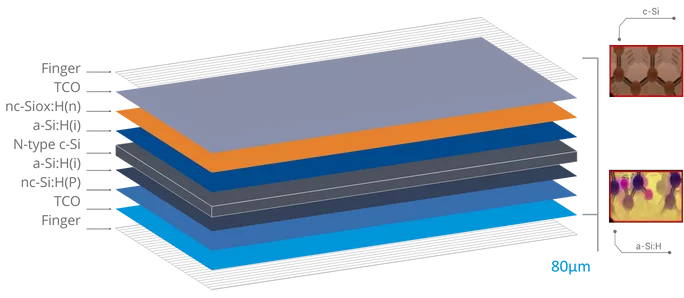

Heterojunction Technology works by engineering the solar cell at the atomic and material-interface level to minimize energy losses and maximize electron flow. Unlike conventional solar cells that rely on a single type of silicon junction, HJT creates a multi-layer, dual-material junction that dramatically improves efficiency, stability, and real-world performance.

- N-type monocrystalline silicon wafer: Thickness is approximately 160–170 microns. The material functions as the primary absorber of sunlight and is resistant to light-induced degradation (LID).

- Front Amorphous Silicon Layer (p-type): Thickness of approximately 5–10 nanometers helps to passivate the surface, effectively reducing electron loss.

- Transparent Conductive Oxide (TCO) Layers: Enables efficient current collection and allows bifacial energy generation by utilizing layers that facilitate efficient current flow.

- Metal contacts: This layered design enhances electrical performance by reducing charge recombination in electrical extraction systems. It enables efficient collection and transfer of electricity while minimizing shading losses compared to conventional cells.

The Evolution of Solar Cell Technology: Why HJT Matters Today

Solar cell technology has evolved through multiple generations, each driven by a fundamental industrial need: generate more electricity from the same surface area, with higher reliability and lower lifetime cost. As solar has moved from an alternative energy source to a core power asset for industries, incremental improvements are no longer enough. This evolution explains why Heterojunction Technology (HJT) has emerged as one of the most important solar innovations today.

1. First Generation: Polycrystalline Solar Cells — Cost Over Performance

Early commercial solar adoption primarily utilized polycrystalline silicon modules, achieving efficiencies between 15% and 17%. While these modules were more affordable to manufacture, they exhibited notable performance drawbacks, including a requirement for extensive land or rooftop space, reduced energy output per square meter, and limited applicability for high-load industrial users. Consequently, during this period, solar energy served mainly as a cost-saving measure rather than a fundamental component of energy strategy.

2. Second Generation: Monocrystalline Silicon — Higher Power Density

The shift to monocrystalline silicon significantly enhanced crystal purity and electron mobility, resulting in solar efficiency rates of 18–20%. This advancement facilitated better space utilization, increased and stabilized energy output, and broader adoption in commercial and industrial rooftop applications. Consequently, solar technology evolved from a support system to a vital power-generation resource for factories and warehouses.

3. PERC Technology: Incremental Efficiency Gains, Structural Limits

The introduction of PERC (Passivated Emitter and Rear Cell) technology substantially improved solar cell efficiencies to 20–21% by minimizing recombination losses on the rear side. However, as PERC became standard in the industry, notable limitations surfaced, including high temperature losses in hot climates, Light-Induced Degradation (LID) of 1.5–2.5% during the initial year, and diminishing efficiency gains as the technology advanced. These issues have begun to impact the economic viability of long-term projects, particularly in industries with space constraints and extended operating hours.

4. The Shift to N-Type Technologies: Performance Over Price

To address the limitations of PERC technology, the industry has transitioned to N-type silicon wafers, which provide advantages including higher carrier lifetime, resistance to Light-Induced Degradation (LID) and light and elevated temperature-induced degradation (LeTID), and enhanced long-term stability. This evolution paved the way for advanced architectures like TOPCon (Tunnel Oxide Passivated Contact) and Heterojunction Technology (HJT), which are engineered for sustainable performance over a 25 to 30-year lifespan rather than seeking immediate short-term benefits.

5. Heterojunction Technology (HJT): A Structural Breakthrough

HJT (Heterojunction with Intrinsic Thin layer) represents a significant departure from traditional solar cell designs, focusing on a hybrid architecture that enhances efficiency. It utilizes an N-type monocrystalline silicon wafer that facilitates effective charge transport, combined with ultra-thin amorphous silicon layers that provide excellent surface passivation. Additionally, transparent conductive oxide (TCO) layers are included to optimize current collection. This innovative structure significantly minimizes recombination losses to less than 1%, resulting in cell efficiencies estimated between 24% and 25%, and module efficiencies surpassing 22% to 23%.

6. Why HJT Matters in Real-World Industrial Conditions

Industrial solar systems are designed to perform in real-world environments, with Heterojunction Technology (HJT) specifically adapted to these conditions. Key performance advantages of HJT include a temperature coefficient of approximately -0.24%/°C, resulting in 4–6% higher energy output under high-temperature conditions. Its degradation rate is low, with ≤0.5% in the first year and about 0.25% annually thereafter, allowing for approximately 90–92% output retention after 30 years. Additionally, HJT provides a higher annual energy yield, offering 8–10% more lifetime energy than PERC technology. The bifaciality factor ranges from 85–95%, leading to a potential 5–25% increase in energy generation in optimized setups. These enhancements lead industrial users to experience lower Levelized Cost of Energy (LCOE) and more reliable long-term financial returns.

7. Why HJT Is Relevant Today—not Tomorrow

HJT technology is becoming increasingly relevant due to the evolving priorities of solar buyers. Contemporary industrial solar projects emphasize the need for maximum energy output given limited space, consistent energy generation in hot climates, long-term financial stability over 25 to 30 years, and alignment with environmental, social, and governance (ESG) objectives, including net-zero and carbon reporting goals. HJT excels in fulfilling these criteria compared to traditional solar technologies.

Why HJT Solar Panels Are a Game-Changer for Industrial & Commercial Projects

1. Superior Energy Conversion Efficiency

HJT (Heterojunction with Intrinsic Thin Layer) panels exhibit significantly higher efficiencies than traditional solar modules, often exceeding 22% and reaching up to approximately 25% in high-end applications. This advantage in efficiency is critically important for industrial rooftops and congested project sites, such as factories, warehouses, and large commercial facilities, where optimizing every square meter of space is essential. The benefits of HJT technology include a reduced system footprint for equivalent energy output and lower balance of system (BOS) costs associated with mounting, wiring, and land use.

The superior performance of Heterojunction Technology panels arises from their unique construction, which combines crystalline silicon with ultra-thin layers of amorphous silicon, enhancing surface passivation and voltage output. Consequently, these panels consistently offer commercial efficiencies in the range of 22% to 24.5%, with potential for even greater performance. The increased energy yield per square meter translates to higher total energy production for the same installed capacity, which is particularly valuable in contexts where roof or land space is constrained.

2. Better Performance in High Temperatures

Heterojunction Technology (HJT) panels exhibit a low temperature coefficient of approximately –0.24 %/°C, indicating that their efficiency decreases less significantly with rising temperatures than that of conventional panels. This characteristic is particularly beneficial in hot climates, which are prevalent at many industrial sites, as it results in more consistent energy generation during peak sunlight hours. Consequently, it effectively supports daytime energy demands with minimal efficiency drop. Key implications include increased energy output during midday and summer months, and enhanced alignment with peak energy demand in industrial settings.

3. Exceptional Bifacial Energy Gain

HJT (Heterojunction Technology) panels feature a significant bifacial capability, allowing them to capture light from both their front and rear surfaces. This characteristic results in bifaciality factors typically ranging from the high 80s to 90s percent, enabling these panels to generate between 10% to 30% more energy by harnessing reflected light from various surfaces such as the ground, rooftops, and light-colored materials like concrete. The bifacial design is particularly advantageous for applications on industrial rooftops, open yards, and reflective sites, enhancing annual energy capture without requiring additional physical space. This is especially beneficial for large commercial installations, as it maximizes energy production in environments with high albedo surfaces, increasing overall efficiency in energy generation.

4. Low Degradation and High Reliability

Heterojunction Technology (HJT) technology exhibits significantly lower degradation rates compared to traditional crystalline panels, particularly due to its minimal light-induced degradation (LID) and strong resistance to potential-induced degradation (PID). This leads to more predictable energy production and secure investment outcomes. Specifically, HJT cells demonstrate a degradation rate of about 0.3–0.5% per year, allowing for increased cumulative energy output over 25-30+ years. The stable performance enhances long-term return on investment (ROI) and financial confidence, resulting in higher energy yields and improved financing conditions for industrial applications. Overall, HJT technology ensures strong performance stability and more favorable investment prospects over decades.

5. Strong Low-Light and Diffuse Light Performance

Heterojunction Technology (HJT) solar panels demonstrate notable performance advantages beyond ideal sunny conditions, effectively functioning in low-light scenarios such as cloudy days and during early morning or late evening hours. Their exceptional passivation and minimal recombination losses contribute to consistent energy production, which is crucial for real-world applications where weather patterns and shading conditions can vary significantly with geography and seasonal changes. This reliability leads to higher performance ratios (PR) under realistic operating circumstances and reduces dependence on peak sunlight hours. As a result, HJT panels offer better energy output and reliability throughout different climate conditions.

6. Longer Lifespan and Warranty Confidence

Combining higher energy yield, temperature resilience, bifacial gains, and slow degradation results in a lower Levelized Cost of Energy (LCOE) and typically shorter payback periods compared to traditional technologies. Panels that generate more energy per installed capacity enhance financial returns and increase asset value. This leads to more competitive energy pricing for industrial power requirements and supports long-term capital planning and sustainability targets. Additionally, many HJT products are accompanied by extended power warranties, often over 30 years, reflecting their durability and slow degradation. This longevity aligns well with industrial planning and financial models that prioritize predictable lifetime output.

Ultra-High Efficiency: More Power from the Same Roof or Land

In industrial and commercial solar projects, space is a strategic asset. Rooftop area, ground availability, and structural limits often define how much solar capacity you can install. This is where ultra-high-efficiency technologies like HJT (Heterojunction Technology) fundamentally change the equation.

1. Higher Efficiency = Higher Power Density

Heterojunction Technology solar panels achieve module efficiencies between 22% and 25%, providing a notably higher power output per square meter than traditional technologies. This advancement fosters several advantages for Commercial and Industrial (C&I) projects, such as enhanced installed capacity on the same area, suitability for space-limited factories and commercial buildings, and increased self-consumption without the need for structural modifications. Ultimately, this technology allows for greater power generation without expanding the physical footprint.

2. Fewer Panels, Smarter Design

Higher wattage per module leads to fewer solar panels required to meet the same megawatt (MW) target, which results in several advantages. These include reduced needs for mounting structures, cabling, and overall installation complexity, as well as a lower total load on rooftops. Operationally, this translates to optimized layouts, decreased Balance of System (BOS) costs, and enhanced compliance with structural constraints.

3. More Real-World Energy, Not Just Higher Ratings

Ultra-high efficiency in HJT (Heterojunction Technology) panels is characterized by better low-light performance during morning, evening, and cloudy conditions, as well as lower temperature losses in hot industrial environments. This results in a higher annual energy yield (kWh/kWp), leading to more usable electricity from the same area and a higher Performance Ratio (PR) across seasons.

4. Land Optimization for Ground-Mount & Captive Solar

Higher efficiency in ground-mounted and solar park projects leads to several advantages, including reduced land requirements per megawatt (MW) and lower civil works, cabling distances, and operational and maintenance (O&M) efforts. This results in a higher energy density per acre. The strategic benefits encompass lower land acquisition and development costs, faster project approvals, and the potential for scalable future expansion.

5. Stronger Financial Outcomes

More power from the same roof or land directly enhances the Payback period, Internal Rate of Return (IRR), and Levelized Cost of Energy (LCOE). This improvement is significant because it transforms fixed space into a high-yield energy asset, thereby maximizing long-term savings and revenue.

Exceptional Performance in High Temperatures

For industrial and commercial solar projects, high ambient temperatures are a daily reality—and a major performance challenge. Conventional solar panels lose significant output as temperatures rise, directly impacting energy generation during peak production hours. Heterojunction Technology (HJT) changes this equation by delivering superior thermal performance exactly when energy demand is highest.

1. Industry-Leading Low Temperature Coefficient

The temperature coefficient is a key metric indicating the power output loss of solar panels as temperature rises. HJT (Heterojunction Technology) modules exhibit a temperature coefficient ranging from –0.24% to –0.26% per °C, outperforming traditional crystalline silicon cells, which typically show coefficients around –0.35% per °C or worse.

This difference is crucial during hot weather; for instance, when the panel temperature increases by 40 °C beyond standard testing conditions, Heterojunction Technology (HJT) panels maintain a higher power output compared to conventional panels, thereby producing more usable energy during peak solar generation hours. In practical terms, HJT panels experience reduced power loss as temperatures rise, ensuring better performance during hot summer days and consistent operation in extreme heat environments, such as tropical, desert, and industrial locations.

2. Higher Energy Output During Peak Load Hours

Industrial facilities experience peak power consumption during mid-day and early afternoon when temperatures are highest. Heterojunction Technology (HJT) solar panels are particularly efficient under these conditions as they lose less energy with increased temperatures and maintain stronger voltage. This results in higher effective power output during peak sunlight, offering key practical benefits, including improved alignment of solar generation with industrial load demands and higher energy capture during optimal sunlight. The low thermal sensitivity of HJT panels allows for more energy generation at peak times, better matching manufacturing load curves, and reducing reliance on grid power when costs are highest. Consequently, businesses can expect lower energy costs and enhanced energy predictability.

3. Architecture That Handles Heat Better

HJT’s innovative cell structure, which layers crystalline silicon with amorphous silicon and incorporates superior surface passivation, effectively mitigates the impact of temperature on charge carriers. This design results in reduced thermal performance losses and stable electrical characteristics, particularly in hot climates. The advanced architecture of HJT cells diminishes internal heat-induced stress, leading to a slowdown in long-term performance degradation, preservation of voltage stability, and elevated overall system reliability. Consequently, users can expect consistent output over a period of 25 to 30 years or more, alongside a reduction in long-term operational and maintenance risks.

4. Ideal for Hot Industrial Environments

Heterojunction Technology (HJT) modules exhibit impressive heat resilience traits, making them particularly effective in various high-temperature environments. These modules perform well in desert and tropical regions, as well as in climates found in Southern Europe, the Middle East, Africa, and India. They are designed for use on urban industrial rooftops that experience intense midday heat, ensuring consistent energy generation in real-world conditions rather than just in ideal laboratory scenarios.

HJT technology is especially suitable for metal rooftops and industrial facilities, including cement plants, steel mills, and refineries, as well as warehouses, logistics parks, and solar parks located in regions characterized by high temperatures. The significance of these modules lies in their ability to deliver reliable energy even under extreme heat, resulting in better annual energy yields compared to conventional solar technologies.

5. Better Lifetime Energy Yield

Over the lifetime of a system, maintaining consistent performance under high temperatures leads to numerous benefits, including greater overall energy production (measured in kWh generated), higher capacity factors, and stronger long-term financial returns. The excellent thermal behavior of Heterojunction Technology (HJT) enhances reliability and reduces performance degradation caused by heat stress, which is particularly significant for industrial budgeting, where every kilowatt-hour (kWh) produced is crucial.

Bifacial Advantage: Unlocking Additional Energy Gains

In modern industrial and commercial solar projects, success is defined not just by installed capacity—but by how much total energy the system produces over its lifetime. This is where Heterojunction Technology (HJT) delivers a decisive edge through its inherent bifacial design, transforming reflected light into real, bankable energy gains.

1. Naturally Bifacial by Design: HJT solar cells are characterized by a symmetrical structure that incorporates transparent conductive layers on both sides, enabling them to effectively absorb sunlight from both the front (direct irradiation) and the rear (reflected and diffused light). This design inherently incorporates bifacial performance, distinguishing it from conventional technologies where bifaciality is either limited or an afterthought. A key advantage of Heterojunction Technology solar cells is their exceptionally high bifaciality, often reaching around 90% or more, making them among the highest performers in the commercial photovoltaic (PV) sector.

2. 10–30% Additional Energy—Without Extra Footprint: Heterojunction Technology (HJT) bifacial modules can enhance energy yield by 10–30% annually by capturing reflected light from various surfaces such as white or reflective industrial rooftops, concrete yards and pavements, light-colored gravel, sand, or soil, and elevated structures like carports and trackers. This increase in energy generation leads to more kilowatt-hours (kWh) produced from the same installation without necessitating additional land, panels, or inverters.

3. Perfect Fit for Industrial & Commercial Sites: Bifacial Heterojunction Technology modules exhibit superior performance in Commercial and Industrial (C&I) projects that typically include large factory rooftops, warehouses and logistics parks, ground-mounted captive power plants, solar carports, and agrivoltaic installations. These environments often provide high reflectivity (albedo), which enhances the rear-side contribution of the modules and increases overall system output.

4. Higher Yield = Lower LCOE: The additional energy collected from the rear side enhances the project’s economic viability by leading to higher annual and lifetime energy production, shorter payback periods, and a reduced Levelized Cost of Energy (LCOE). This strategic advantage results in improved return on investment (ROI) without a corresponding increase in capital expenditures (CAPEX), thereby enhancing bankability and the long-term asset value.

5. More Consistent Generation Across the Day: Bifacial HJT modules enhance energy generation quality by capturing diffused and reflected light during mornings and evenings and improving output under cloudy or variable conditions. This leads to a higher Performance Ratio (PR) and results in smoother and more reliable daily generation profiles.

Longer Lifespan & Lower Degradation Rates

- Built for Long-Term Stability: HJT cells combine crystalline silicon with ultra-thin amorphous silicon layers on both sides of the wafer. This hybrid structure delivers excellent surface passivation, dramatically reducing electron recombination—one of the primary causes of long-term performance loss in solar modules. The result is a panel that is inherently more stable, less stressed, and better protected against ageing mechanisms.

- Lower Degradation, Year After Year: Heterojunction Technology (HJT) offers significant advantages due to its exceptionally low degradation profile. Firstly, it exhibits No Light-Induced Degradation (LID), maintaining stable power output from Day 1, contrasting with many traditional technologies that experience early performance drops. It also features minimal first-year degradation of approximately 1% or less, ensuring quicker attainment of projected energy yields. Additionally, HJT modules suffer very low annual degradation, around 0.25% thereafter, allowing them to retain over 90% of their rated power even after 30 years. This performance translates to increased cumulative energy generation for industrial and commercial solar plants without the need for expanding footprint or infrastructure.

- Longer Lifespan = Higher Lifetime Energy Yield: Lower degradation in HJT (Heterojunction) modules contributes to a prolonged productive lifespan, with an operational efficiency expected for 30 years or more. This extended lifespan, backed by performance warranties, results in multiple benefits: increased total kilowatt-hour (kWh) generation, a decreased Levelized Cost of Energy (LCOE), and a minimized risk of the need for mid-life repowering or module replacement.

HJT vs PERC vs TOPCon: A Technology Comparison

| Feature / Metric | PERC | TOPCon | HJT (Heterojunction Technology) |

|---|---|---|---|

| Typical Module Efficiency | ~20.5%–22% | ~21.5%–23.2% | ~21.5%–23.5% (higher end of commercial range) |

| Temperature Coefficient (Pmax) | ~-0.34% to -0.40%/°C | ~-0.30% to -0.32%/°C | ~-0.24% to -0.27%/°C (best hotspot performance) |

| First-Year Degradation | ~2% | ~1.0–1.5% | ~≤1.0% |

| Annual Degradation (Years 2+) | ~0.45–0.55% | ~0.35–0.45% | ~0.25–0.35% |

| Bifacial Gain Potential | ~70% | ~80–85% | ~90–95% |

| LID / LeTID Sensitivity | Medium | Low | Very Low |

| Typical Production Cost | Lowest | Moderate (+3–7% vs PERC) | Highest (+8–15% vs PERC) |

| Best Use Cases | Cost-efficient baseline | Most utility & C&I fields | High-yield, premium sites with heat/diffuse light challenges |

Manufacturing Sustainability: Low-Carbon Solar for Net-Zero Goals

1. Reduced Carbon Footprint During Manufacturing

Heterojunction Technology (HJT) offers significant sustainability advantages primarily due to its lower temperature manufacturing process. Unlike traditional silicon photovoltaic (PV) manufacturing, such as Passivated Emitter and Rear Cell (PERC) technology, which requires high-temperature steps (800–1000 °C), HJT functions at much lower temperatures (150–250 °C). This reduced thermal requirement leads to substantially lower energy consumption and a corresponding decrease in carbon emissions during module production.

Manufacturers have reported carbon footprints around 366 g CO₂-eq/W, with the potential to reduce this figure below 300 g CO₂-eq/W as production techniques advance and energy sources become greener. Additionally, HJT’s reliance on less energy-intensive production and thinner wafers not only mitigates emissions but also minimizes material stress, contributing to the creation of lighter and more durable panels.

2. Lifecycle Carbon Metrics: HJT vs Other Technologies

Independent lifecycle analyses indicate that HJT modules often surpass conventional technologies in environmental metrics, incorporating balance-of-system emissions. HJT systems demonstrate a lower carbon footprint, with about 13 g CO₂-eq/kWh over a 30-year rooftop project, compared to 14.7 g for TOPCon. They also result in higher net avoided greenhouse gas emissions due to greater lifetime energy yield and exhibit a reduced carbon payback period by roughly 10–11% versus TOPCon and baseline modules. Additionally, advanced low-carbon HJT modules have lower manufacturing energy consumption at 105–115 MWh/MW and carbon footprints as low as 285 kg CO₂-eq/kWp in next-generation products.

3. Industrial Impact for Net-Zero Goals

Manufacturing sustainability strategies offer several advantages: faster decarbonization enables earlier neutralization of emissions, enhancing progress toward net-zero goals; stronger ESG reporting through quantifiable lifecycle carbon reductions aids corporate disclosures; reduced material and energy use from thinner wafers and lower process temperatures decreases emissions and resource demand; and long-term emissions avoidance is achieved by Heterojunction Technology panels, which generate more energy over their lifespan, further supporting net-zero initiatives.

Applications of HJT Solar Technology in Industrial Projects

1. Industrial Rooftop & C&I Solar Systems

HJT (Heterojunction Technology) is an efficient solar panel technology ideal for installation on factory rooftops, warehouses, and manufacturing units, especially where roof space is limited and there is a high demand for power during the day. Its superior efficiency enables greater energy capacity within the same physical area. Additionally, the technology features a low temperature coefficient, which enhances its performance even on hot industrial roofs. The expected outcome of utilizing HJT is the maximization of captive power generation, providing a stable energy output over multiple decades.

2. Solar Carports, Canopies & Industrial Yards

Heterojunction Technology utilizes its high bifacial capability to excel in applications such as carports, logistics yards, and loading areas, where it benefits from the abundant reflected light from concrete or paved surfaces. This approach transforms underutilized spaces into valuable energy-producing assets while also offering shade and protection. The outcome is a higher energy yield from dual-use infrastructure without the need for additional land.

3. Building-Integrated Photovoltaics (BIPV) & Façade Integration

Heterojunction Technology (HJT )technology is increasingly utilized in industrial façades, vertical walls, and architectural solar integration due to its effective performance in low and diffuse light conditions. It allows for power generation even in non-ideal orientations, thus supporting energy production without requiring additional roof or land space. This capability leads to expanded solar capacity within the existing industrial footprint. Innovative applications of Heterojunction Technology include solar façades on industrial buildings, where photovoltaic panels are seamlessly integrated into the architecture. This method not only harnesses clean energy but also mitigates internal heat gain, resulting in reduced electricity consumption and cooling demands in facilities such as warehouses and data centers.

4. Off-Grid & Hybrid Applications

HJT (Heterojunction Technology) solar panels are particularly effective when combined with battery storage and hybrid energy systems, especially in manufacturing settings that seek increased self-consumption or independence from the grid. The benefits include a stable output profile that enhances battery utilization, ensuring consistent energy generation that supports critical operations and increases resilience in areas where the grid is unstable.

This results in more predictable and controllable clean energy for industrial operations. HJT solar technology is especially advantageous for industrial sites located in remote regions, such as mining camps, agricultural processing facilities, and off-grid operations, due to its excellent performance in low-light conditions and stable energy output, making it a valuable solution where grid reliability is either insufficient or expensive to maintain.

Cost vs Value: Understanding the True Economics of HJT

When evaluating Heterojunction Technology (HJT) for industrial solar, it’s essential to look beyond upfront price per watt and understand how long-term performance influences overall economic returns. HJT’s economics aren’t defined simply by higher initial cost—they’re shaped by lifetime energy production, degradation performance, and operational value.

1. Upfront Cost — A Premium Investment

HJT (Heterojunction Technology) panels are generally more expensive per watt than traditional PERC (Passivated Emitter and Rear Cell) and some TOPCon (Tunnel Oxide Passivated Contact) modules. The higher costs are attributed to several factors: the need for specialized manufacturing equipment and processes, increased material costs such as low-temperature silver paste and n-type wafers, and a lower manufacturing scale resulting in reduced production yields. As a point of reference, while PERC panels are priced within a baseline cost range, HJT panels command a premium of approximately 15–25% per watt, reflecting their advanced performance capabilities alongside their limited manufacturing scale.

2. Value Comes Through Lifetime Performance

Heterojunction Technology (HJT) offers significant advantages in energy generation and cost efficiency. It produces higher annual and lifetime energy yields due to its increased efficiency, superior temperature performance, and minimal degradation of approximately 0.25% per year. Additionally, HJT can utilize enhanced bifacial gains where suitable, leading to substantial electricity generation over a 25-30 year project lifespan, effectively offsetting initial costs. Moreover, despite a higher upfront investment, HJT can achieve a lower Levelized Cost of Energy (LCOE), resulting in reduced costs per kilowatt-hour (kWh) throughout the system’s operational life. Comparative analyses over 25 years demonstrate that HJT surpasses PERC and TOPCon technologies in achieving a lower LCOE when performance benefits are integrated.

3. Real World Examples of Economics in Action

The section discusses the payback and return on investment (ROI) of Heterojunction Technology (HJT) solar panels. Although HJT may require a higher initial capital expenditure (CAPEX), its benefits include increased energy output and reduced degradation, contributing to a payback period that is shorter or comparable to traditional panels, particularly in climates with high irradiance or temperatures. In simulations, Heterojunction Technology panels have been shown to generate 10-20% more cumulative energy over a span of 25 years compared to conventional panels. They also exhibit lower operational losses due to minimal light-induced degradation (LID) and improved performance in high temperatures, along with enhanced bifacial energy contributions when appropriately installed.

4. Value Beyond Electricity — Strategic Benefits

Sustainability and decarbonization are enhanced by heterojunction technology, which boasts a longer lifespan and reduced performance decline, leading to lower lifecycle emissions and maintenance needs. This improvement is pivotal for ESG reporting and strategic planning towards net-zero goals. Additionally, HJT’s low degradation and high reliability contribute to more predictable cash flows, enhancing financial modeling for industrial renewable energy initiatives—a significant factor for lenders and investors. Furthermore, HJT’s ability to generate more watts per panel can decrease the number of modules required, thus potentially lowering balance-of-system (BOS) costs related to racking, wiring, and labor while also easing pressures on land or roof space utilization.

The Future of Solar Is Heterojunction Technology

The Future of Solar Is Heterojunction Technology is being shaped by the industry’s shift from short-term efficiency gains to long-term performance, reliability, and sustainability. As industrial and commercial energy consumers demand higher output from limited space, Heterojunction Technology (HJT) stands out by delivering superior efficiency, excellent performance in high temperatures and low-light conditions, and significantly lower degradation over time. Its unique cell structure enables stable power generation from day one, ensuring predictable energy yields and stronger financial returns across a 25–30 year project lifecycle.

Beyond performance, Heterojunction Technology supports the future of clean energy through low-temperature manufacturing processes that reduce carbon footprint and align with net-zero and ESG goals. Most importantly, HJT is future-ready—serving as a strong foundation for next-generation innovations like tandem solar cells. Together, these advantages position Heterojunction Technology not as an alternative, but as the defining solar technology of the future, delivering smarter, more resilient, and more valuable solar power for industrial growth.

Conclusion

Heterojunction Technology is redefining what industrial solar can achieve—combining high efficiency, long-term stability, low degradation, and sustainability into a single, future-ready solution. For manufacturers and energy-intensive businesses, Heterojunction Technology is not just about generating power; it’s about securing predictable energy costs, maximizing lifetime returns, and building a resilient pathway toward net-zero operations. As solar investments increasingly become strategic business decisions, choosing the right technology today determines performance and profitability for decades to come.

Now is the time to think beyond conventional solar.

If you’re planning a new solar project or upgrading an existing one, explore how Heterojunction Technology can unlock higher value from the same footprint. Connect with our solar experts to evaluate HJT for your facility and future-proof your energy strategy—because the next era of industrial power starts now.

FAQs

1. What is Heterojunction Technology (HJT) in solar panels?

Heterojunction Technology (HJT) combines crystalline silicon with thin layers of amorphous silicon to reduce energy losses at the cell level. This advanced structure enables higher efficiency, better temperature performance, and longer operational life compared to conventional solar technologies.

2. Why is HJT considered the future of solar technology?

HJT addresses the key challenges of modern solar projects—space constraints, long-term reliability, and sustainability. With higher efficiency, extremely low degradation, and compatibility with next-generation tandem technologies, HJT is designed to deliver value not just today, but for decades.

3. How does HJT perform in high-temperature and low-light conditions?

HJT panels have an excellent temperature coefficient and superior low-light response, allowing them to generate stable power even in hot climates and during early mornings, evenings, or cloudy conditions—ideal for industrial and commercial applications.

4. What is the lifespan of HJT solar panels?

HJT modules are engineered for long-term performance, typically offering operational lifespans of 30 years or more. Their low degradation rates ensure higher retained power output throughout the system’s life.

5. Is HJT suitable for industrial and large manufacturing facilities?

Yes. HJT is particularly well-suited for large manufacturing units where space optimization, energy reliability, and long-term cost predictability are critical. Its high energy density and stable output make it a strong choice for C&I rooftops and solar parks.