Table of Contents

Introduction

In today’s fast-changing landscape of industrial automation, the demand for systems that offer efficient, reliable, and remote monitoring and control has never been greater. Central to this technological evolution is the Remote Terminal Unit (RTU)—a sophisticated, microprocessor-based device that acts as a critical bridge between physical equipment in the field and centralized control systems. A remote terminal unit is specially designed to ensure smooth communication and data flow between field instruments and control centers, making it an essential component in modern industrial infrastructures.

Remote terminal units play a vital role in Supervisory Control and Data Acquisition (SCADA) systems by enabling real-time data collection, monitoring, and control. Industries such as power generation, oil and gas, water and wastewater treatment, and transportation depend heavily on the capabilities of remote terminal units to maintain efficient and safe operations over large geographical areas.

The primary function of a remote terminal unit is to collect data from connected sensors and field devices, process this data internally, and then transmit it to a central control system. In return, it receives instructions from the control center to carry out specific actions—like starting or stopping machinery, opening or closing valves, or modifying operational parameters. This two-way communication mechanism ensures industrial systems can respond swiftly to changing conditions and operate with maximum effectiveness.

The architecture of a remote terminal unit typically includes the following components:

- Central Processing Unit (CPU): The core of the remote terminal unit, responsible for executing logic, processing data, and managing communication protocols.

- Input/Output (I/O) Modules: These modules allow the remote terminal unit to interface with external field devices, enabling it to receive sensor inputs and transmit control outputs.

- Communication Interfaces: These enable the remote terminal unit to exchange data with central systems, often supporting standardized communication protocols such as Modbus, DNP3, or IEC 60870-5-101/104.

- Power Supply: The remote terminal unit is designed for reliability, often equipped with battery backup or solar power options to maintain operation in remote or off-grid locations.

As industries move toward more intelligent and interconnected systems, the remote terminal unit continues to evolve, playing an increasingly important role in enabling smart, responsive, and resilient industrial operations.

Modern RTUs have evolved to meet the demands of increasingly complex industrial environments. Advancements include enhanced processing capabilities, support for multiple communication protocols, improved cybersecurity features, and the ability to operate in harsh environmental conditions. These improvements have expanded the applicability of RTUs, making them indispensable tools in the pursuit of automation and digital transformation.

This comprehensive exploration delves into the architecture, applications, and recent advancements of Remote Terminal Units. By understanding the integral role RTUs play in industrial automation, stakeholders can make informed decisions to optimize operations, enhance safety, and drive innovation.

1. Understanding the Remote Terminal Unit (RTU)

A Remote Terminal Unit (RTU) is a microprocessor-based electronic device that serves as a critical interface between physical equipment and centralized control systems in industrial automation. RTUs are designed to collect data from field instruments, process this information, and transmit it to a central system, such as a Supervisory Control and Data Acquisition (SCADA) system. Conversely, they receive commands from the central system to control connected devices, enabling efficient and remote management of industrial processes.

Core Functions of RTUs

- Data Acquisition: RTUs gather real-time data from various sensors and field devices, monitoring parameters like temperature, pressure, flow rates, and equipment status.

- Data Processing: The collected data is processed locally within the RTU, which may include filtering, scaling, or performing basic calculations to ensure accurate and meaningful information is transmitted.

- Communication: RTUs transmit processed data to central control systems using various communication protocols and receive operational commands in return.

- Control Operations: Based on received commands, RTUs can execute control actions such as opening or closing valves, starting or stopping motors, and adjusting setpoints to maintain optimal process conditions.

2. Historical Context of RTUs

The Remote Terminal Unit (RTU) has been a cornerstone in the evolution of industrial automation, serving as a vital link between field devices and centralized control systems. Its development reflects the broader advancements in technology and the growing need for efficient, reliable remote monitoring and control.

Origins and Early Development

The concept of the Remote Terminal Unit emerged in the 1960s, coinciding with the rise of electronic control systems in industries such as oil and gas. Early RTUs were designed to collect data from remote sensors and transmit it to central control rooms, enabling operators to monitor processes without being physically present at the site. These initial units were relatively simple, focusing primarily on data acquisition and transmission.

Integration with SCADA Systems

As industrial processes became more complex, the need for comprehensive monitoring and control systems led to the development of Supervisory Control and Data Acquisition (SCADA) systems. RTUs became integral components of SCADA architectures, acting as intermediaries that gathered data from field devices and executed control commands from the central system. This integration allowed for more responsive and efficient management of industrial operations.

Technological Advancements

Over the decades, RTUs have evolved significantly. Advancements in microprocessor technology have enhanced their processing capabilities, allowing for local data processing and decision-making. Modern RTUs support various communication protocols, such as Modbus and DNP3, facilitating interoperability with diverse systems. Additionally, improvements in power supply options, including solar and battery backups, have enabled RTUs to operate reliably in remote and harsh environments.

Contemporary Applications

Today, Remote Terminal Units are employed across various industries, including power generation, water treatment, and transportation. They play a crucial role in monitoring and controlling distributed assets, ensuring operational efficiency, safety, and compliance with regulatory standards.

In summary, the Remote Terminal Unit has transitioned from a basic data collection device to a sophisticated component essential for modern industrial automation. Its continued evolution underscores its importance in facilitating effective remote monitoring and control in an increasingly connected world.

3. Architecture of a Remote Terminal Unit

A Remote Terminal Unit (RTU) is a microprocessor-based device that interfaces physical equipment with centralized control systems, such as SCADA (Supervisory Control and Data Acquisition) systems. The architecture of an RTU is designed to facilitate efficient data acquisition, processing, and communication, enabling remote monitoring and control of industrial processes.

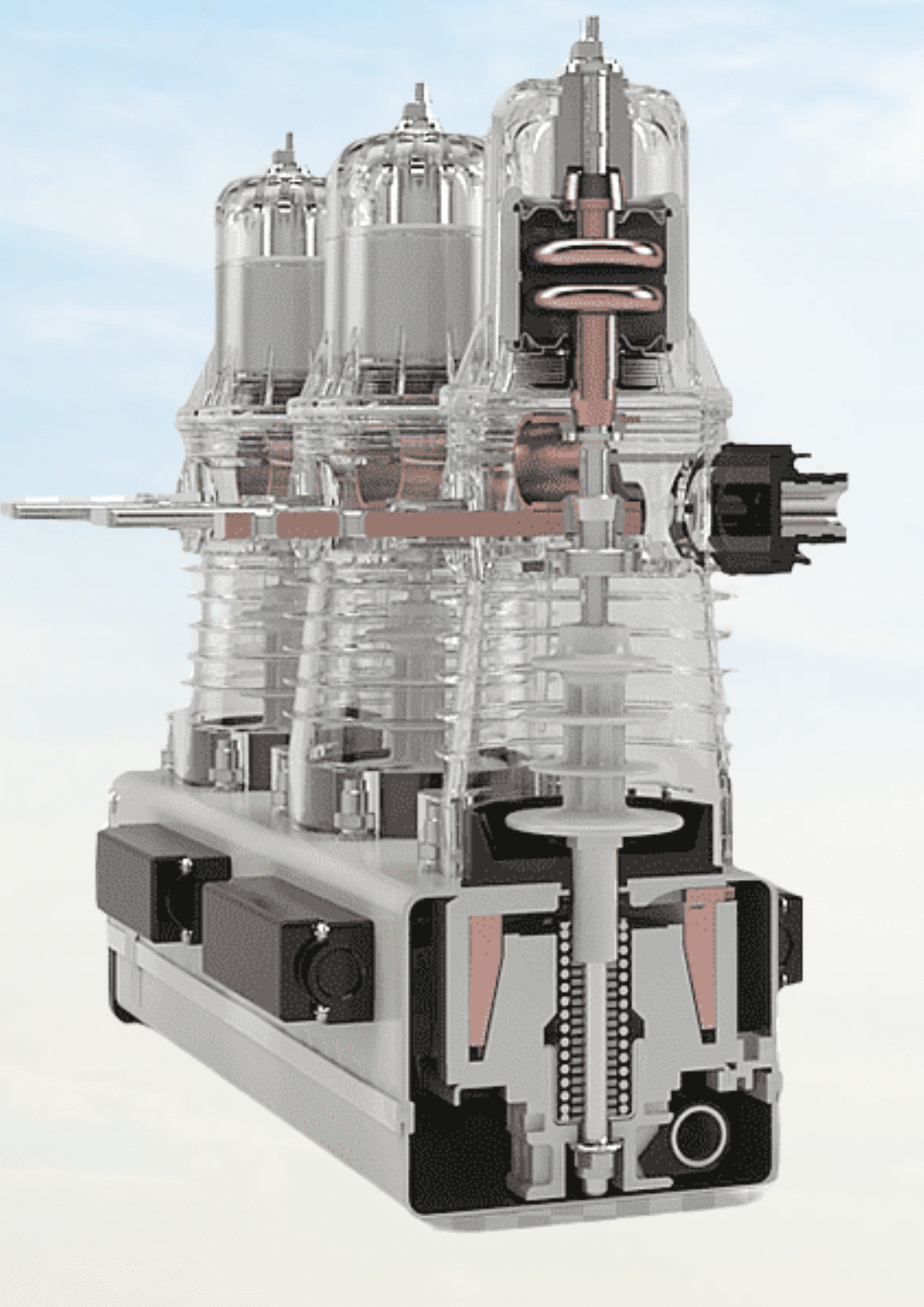

Core Components of RTU Architecture

- Central Processing Unit (CPU):

The CPU is the brain of the RTU, responsible for executing control algorithms, processing data from field devices, and managing communication with the central control system. Modern CPUs in RTUs are designed for real-time processing and may include features like multitasking and error handling to ensure reliable operation. - Input/Output (I/O) Modules:

- Analog Inputs (AI): These inputs receive continuous signals from sensors measuring parameters such as temperature, pressure, or flow rates.

- Digital Inputs (DI): These inputs detect discrete signals, such as the open or closed status of a switch.

- Analog Outputs (AO): These outputs send continuous control signals to actuators, like adjusting a valve position.

- Digital Outputs (DO): These outputs send discrete signals to control devices, such as turning a pump on or off.

- Communication Interfaces:

RTUs are equipped with communication modules that support various protocols (e.g., Modbus, DNP3, IEC 60870-5-101/104) to facilitate data exchange with central systems and other devices. These interfaces can include serial ports, Ethernet ports, or wireless communication modules, depending on the application requirements. - Power Supply:

A reliable power supply is crucial for RTU operation, especially in remote locations. RTUs may be powered by AC mains, DC sources, batteries, or solar panels. Incorporating backup power options ensures continuous operation during power outages. - Enclosure:

RTUs are often housed in rugged enclosures designed to protect internal components from environmental factors such as dust, moisture, and temperature extremes. The enclosure’s design ensures the RTU’s durability and longevity in harsh industrial environments. - Memory and Storage:

RTUs include memory components for storing the operating system, application programs, configuration settings, and historical data. Non-volatile memory ensures data retention even during power interruptions. - Real-Time Clock (RTC):

An RTC provides accurate timekeeping for timestamping events and synchronizing data with the central control system. This feature is essential for maintaining data integrity and facilitating event analysis.

4. Working Mechanism of RTUs

A Remote Terminal Unit (RTU) is a microprocessor-based device that serves as a critical interface between physical equipment and centralized control systems, such as SCADA (Supervisory Control and Data Acquisition) systems. RTUs are designed to collect data from field instruments, process this information, and transmit it to a central system. Conversely, they receive commands from the central system to control connected devices, enabling efficient and remote management of industrial processes.

1. Data Acquisition

RTUs gather data from various sensors and field devices that monitor parameters like temperature, pressure, flow rates, and equipment status. These sensors provide analog or digital signals, which the RTU’s input modules capture for processing. This real-time data collection is essential for monitoring the health and performance of industrial systems.

2. Data Processing

Once the data is acquired, the RTU’s central processing unit (CPU) processes the information. This may involve filtering noise, scaling signals, converting units, or performing calculations to derive meaningful insights. Some RTUs also support local control logic, allowing them to make autonomous decisions based on predefined conditions, enhancing system responsiveness and reliability.

3. Communication with Central Systems

Processed data is transmitted from the RTU to central control systems using various communication protocols such as Modbus, DNP3, or IEC 60870-5-101/104. These protocols ensure reliable and standardized data exchange between the RTU and supervisory systems. Communication can occur over wired connections like Ethernet or serial lines, or wirelessly via cellular or radio networks, depending on the application’s requirements.

4. Execution of Control Commands

In addition to sending data, RTUs receive control commands from central systems. These commands instruct the RTU to perform specific actions, such as opening or closing valves, starting or stopping motors, or adjusting setpoints. The RTU translates these commands into appropriate signals for the connected field devices, facilitating remote control of industrial processes.

5. Monitoring and Diagnostics

Modern RTUs include diagnostic features that monitor their own health and the status of connected devices. They can detect issues like communication failures, power supply problems, or sensor malfunctions, and report these anomalies to central systems. This proactive monitoring enables timely maintenance and reduces system downtime.

In summary, the Remote Terminal Unit operates as a pivotal component in industrial automation, bridging the gap between field devices and centralized control systems. Its ability to acquire, process, and transmit data, as well as execute control commands, makes it indispensable for efficient and reliable operation of complex industrial processes.

5. Key Features of Modern Remote Terminal Units

Modern Remote Terminal Units (RTUs) have evolved into sophisticated devices integral to industrial automation, offering a range of features that enhance monitoring, control, and communication capabilities. Below are key features characterizing contemporary RTUs:

1. Advanced Communication Protocols

Modern RTUs support a variety of communication protocols, including Modbus, DNP3, and IEC 60870-5-101/104, facilitating seamless integration with SCADA systems and other control platforms. These protocols enable reliable and standardized data exchange between field devices and central control systems.

2. Robust Data Acquisition and Processing

Equipped with powerful microprocessors, RTUs can efficiently collect and process data from various sensors and actuators. They perform real-time data acquisition, filtering, and analysis, ensuring accurate monitoring of industrial processes.

3. Flexible Input/Output Configurations

RTUs offer configurable analog and digital input/output modules, allowing customization based on specific application requirements. This flexibility enables RTUs to interface with a wide range of field devices, enhancing their adaptability in diverse industrial settings.

4. Rugged and Durable Design

Designed for deployment in harsh environments, modern RTUs feature rugged enclosures that protect against dust, moisture, and extreme temperatures. This durability ensures reliable operation in remote and challenging locations.

5. Local Control Capabilities

Beyond data acquisition, RTUs can execute control functions locally. They support programming languages such as ladder logic and structured text, allowing for the implementation of complex control strategies directly within the RTU.

6. Energy Efficiency and Power Management

Modern RTUs are designed with energy efficiency in mind, often featuring low-power consumption modes and support for renewable energy sources like solar panels. They may include battery backup systems to ensure uninterrupted operation during power outages.

7. Scalability and Integration

RTUs are scalable, allowing for the addition of more I/O modules or communication interfaces as system requirements grow. They can be integrated into larger automation systems, working alongside Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) to provide comprehensive monitoring and control solutions.

8. Enhanced Security Features

With the increasing importance of cybersecurity in industrial systems, modern RTUs incorporate security features such as authentication protocols, encryption, and secure communication channels to protect against unauthorized access and data breaches.

9. Remote Diagnostics and Maintenance

RTUs support remote diagnostics, allowing operators to monitor system performance, update firmware, and troubleshoot issues without the need for on-site visits. This capability reduces maintenance costs and improves system uptime.

10. Integration with Intelligent Electronic Devices (IEDs)

Modern RTUs can communicate with IEDs, facilitating advanced functionalities like protective relaying and fault detection in power systems. This integration enhances the overall efficiency and reliability of industrial operations.

In summary, the modern Remote Terminal Unit is a versatile and robust device that plays a critical role in industrial automation. Its advanced features enable efficient data acquisition, processing, and control, ensuring reliable operation across various industries and applications.

6. Communication Protocols in RTUs

Remote Terminal Units (RTUs) are pivotal components in industrial automation, facilitating communication between field devices and central control systems like SCADA. To ensure seamless data exchange, RTUs support a variety of communication protocols, each tailored to specific application needs. Below is an overview of the most prevalent protocols employed in RTUs:

1. Modbus (Modbus RTU & Modbus TCP)

- Overview: Established in 1979, Modbus is a widely adopted open protocol in industrial settings.

- Variants:

- Modbus RTU: Operates over serial communication lines (e.g., RS-232, RS-485).

- Modbus TCP: Functions over Ethernet networks.

- Applications: Ideal for straightforward master-slave communication, commonly used in process control and automation systems.

2. DNP3 (Distributed Network Protocol)

- Overview: DNP3 is designed for reliable communication in challenging environments, particularly in utilities like electric and water companies.

- Features:

- Supports event-driven reporting and time-stamped data.

- Offers robust error checking and data integrity mechanisms.

- Applications: Widely used in SCADA systems for electric utility automation.

3. IEC 60870-5 Series

- Overview: A set of international standards for telecontrol in electrical engineering and power system automation.

- Variants:

- IEC 60870-5-101: Serial communication.

- IEC 60870-5-104: Network communication over TCP/IP.

- Applications: Predominantly used in European power systems for monitoring and control.

4. HART (Highway Addressable Remote Transducer Protocol)

- Overview: A hybrid protocol combining analog and digital communication.

- Features:

- Allows digital communication over existing 4–20 mA analog wiring.

- Supports both point-to-point and multidrop configurations.

- Applications: Commonly used in process industries for smart field devices.

5. CANopen

- Overview: A communication protocol based on the Controller Area Network (CAN) for embedded systems.

- Features:

- Supports real-time data exchange.

- Offers standardized device profiles for interoperability.

- Applications: Used in automation, medical equipment, and transportation systems.

6. WITS (Worldwide Industrial Telemetry Standards)

- Overview: A suite of protocols designed for the water industry, enhancing DNP3 with additional features.

- Features:

- Provides secure authentication.

- Facilitates plug-and-play device integration.

- Applications: Used in water and wastewater telemetry systems.

7. MQTT (Message Queuing Telemetry Transport)

- Overview: A lightweight, publish-subscribe network protocol that transports messages between devices.

- Features:

- Designed for low-bandwidth, high-latency networks.

- Supports secure communication via TLS.

- Applications: Increasingly used in IoT applications and remote monitoring systems.

8. OPC (OLE for Process Control)

- Overview: A series of standards for industrial telecommunication.

- Features:

- Facilitates interoperability between different hardware and software.

- Supports real-time data access and historical data retrieval.

- Applications: Widely used in process control and manufacturing systems.

9. Physical Communication Interfaces

- Serial Interfaces: RS-232, RS-485, and RS-422 are commonly used for point-to-point and multi-drop configurations.

- Ethernet: Provides high-speed communication and supports multiple protocols over TCP/IP.

- Wireless: RTUs may utilize wireless technologies like GSM, radio, or satellite for remote communication

7. RTU vs PLC: Understanding the Difference

| Feature | Remote Terminal Unit (RTU) | Programmable Logic Controller (PLC) |

|---|---|---|

| Primary Function | Remote monitoring and control, especially over wide geographic areas. | Local control and automation of machinery and processes within a facility. |

| Typical Use Cases | Utilities (e.g., water treatment, power distribution), oil and gas pipelines, remote stations. | Manufacturing lines, assembly processes, packaging systems, and other localized industrial operations. |

| Environment | Designed to operate in harsh, remote, and unattended locations. | Optimized for controlled environments like factories and industrial plants. |

| Communication | Utilizes various communication protocols (e.g., Modbus, DNP3) and supports wireless communication. | Primarily uses wired communication protocols; integration with SCADA systems is common. |

| Power Supply | Often equipped with battery backups or solar power systems for remote operation. | Typically powered by the facility’s main power supply. |

| Processing Power | Generally less processing power, focusing on data acquisition and transmission. | Higher processing capabilities for complex control algorithms and real-time processing. |

| Programming | May have limited or fixed programming capabilities; often configured remotely. | Highly programmable using languages like ladder logic, structured text, and function block diagrams. |

| Cost | Can be more expensive due to ruggedization and communication features. | Generally more cost-effective for local automation tasks. |

8. Applications of Remote Terminal Units

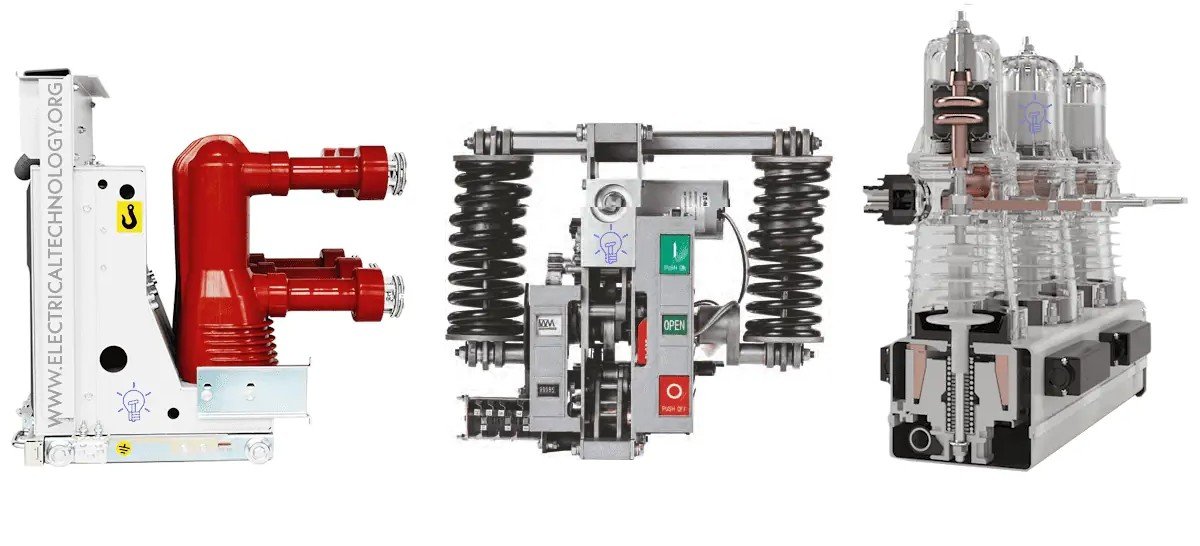

1. Power Generation and Distribution

In the energy sector, Remote Terminal Units are essential for:

- Monitoring substations and transformers.

- Managing load distribution and detecting faults.

- Integrating with Supervisory Control and Data Acquisition (SCADA) systems for real-time data acquisition and control.

Their ability to operate in remote and harsh environments ensures consistent power delivery and system reliability.

2. Oil and Gas Industry

Remote Terminal Units are utilized in the oil and gas sector for:

- Monitoring pipeline pressures and flow rates.

- Controlling remote valves and compressors.

- Detecting leaks and ensuring safety compliance.

Their deployment enhances operational efficiency and safety in both upstream and downstream operations.

3. Water and Wastewater Management

In water resource management, Remote Terminal Units contribute by:

- Monitoring water levels, flow rates, and quality parameters.

- Controlling pumps and valves in treatment plants.

- Ensuring compliance with environmental regulations.

Their integration facilitates automated control and timely responses to system anomalies.

4. Agriculture and Irrigation Systems

In agricultural applications, Remote Terminal Units are employed to:

- Monitor soil moisture and weather conditions.

- Control irrigation schedules and water distribution.

- Optimize resource utilization and crop yields.

Their use supports precision agriculture practices, leading to sustainable farming operations.

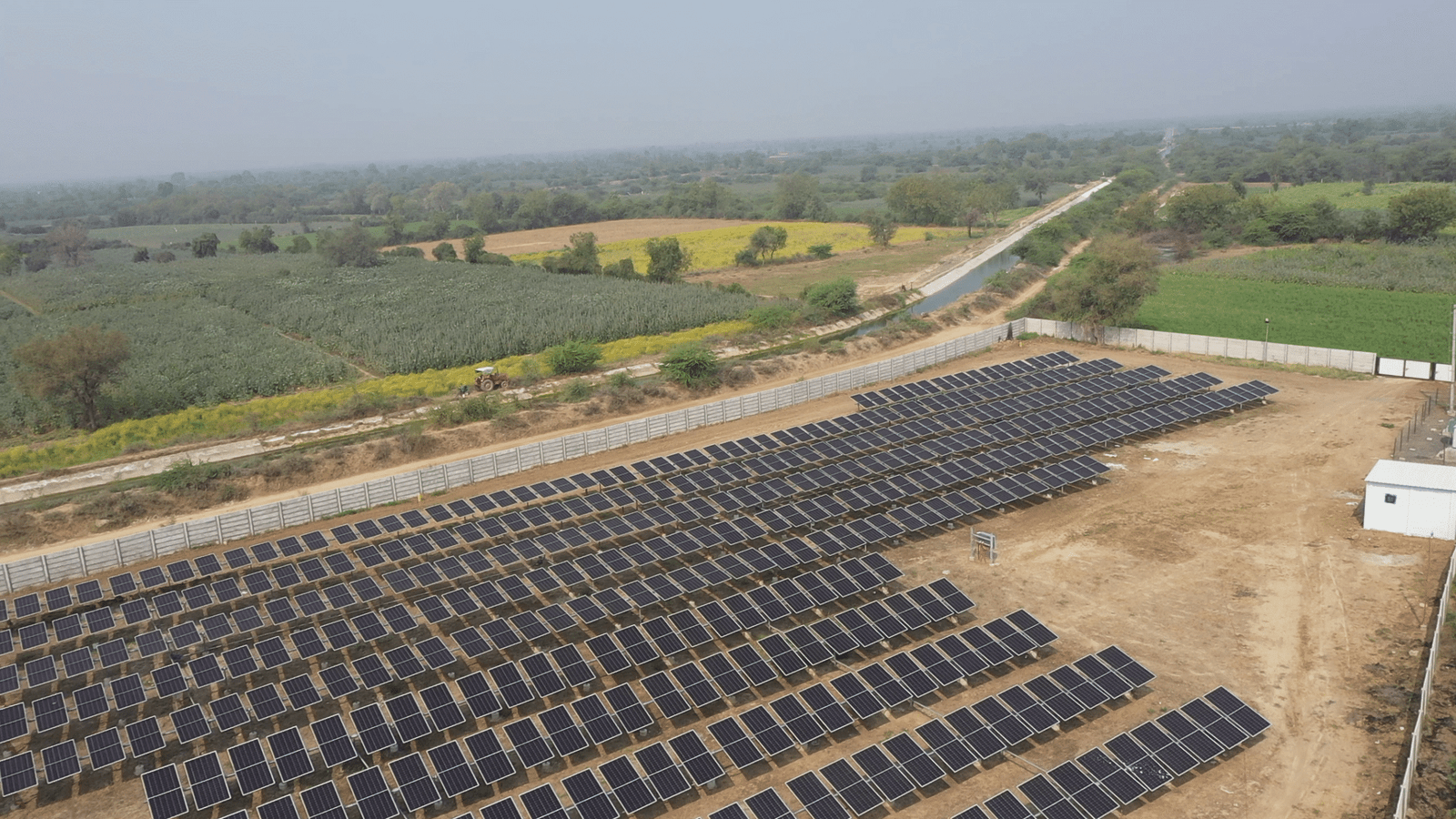

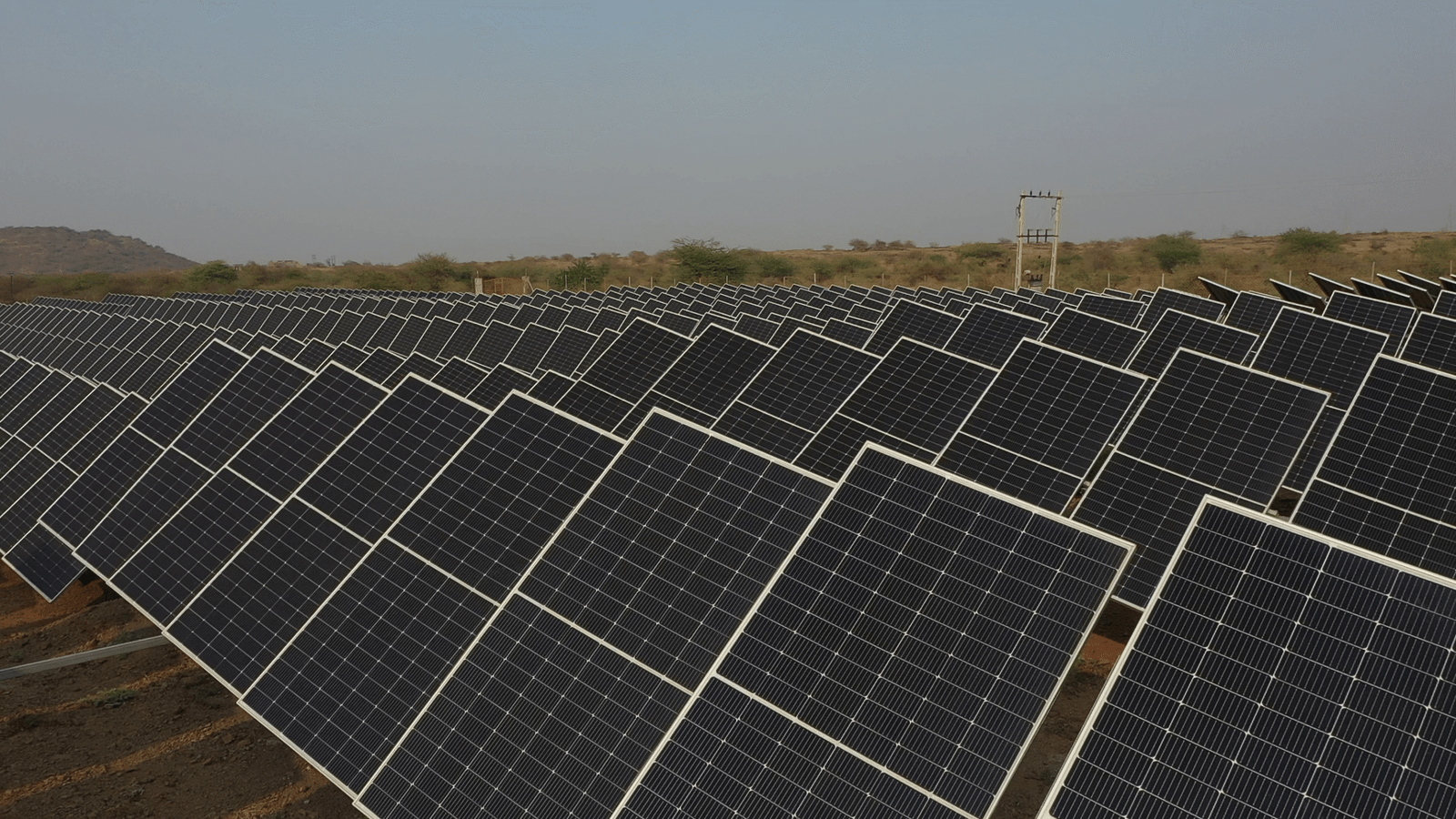

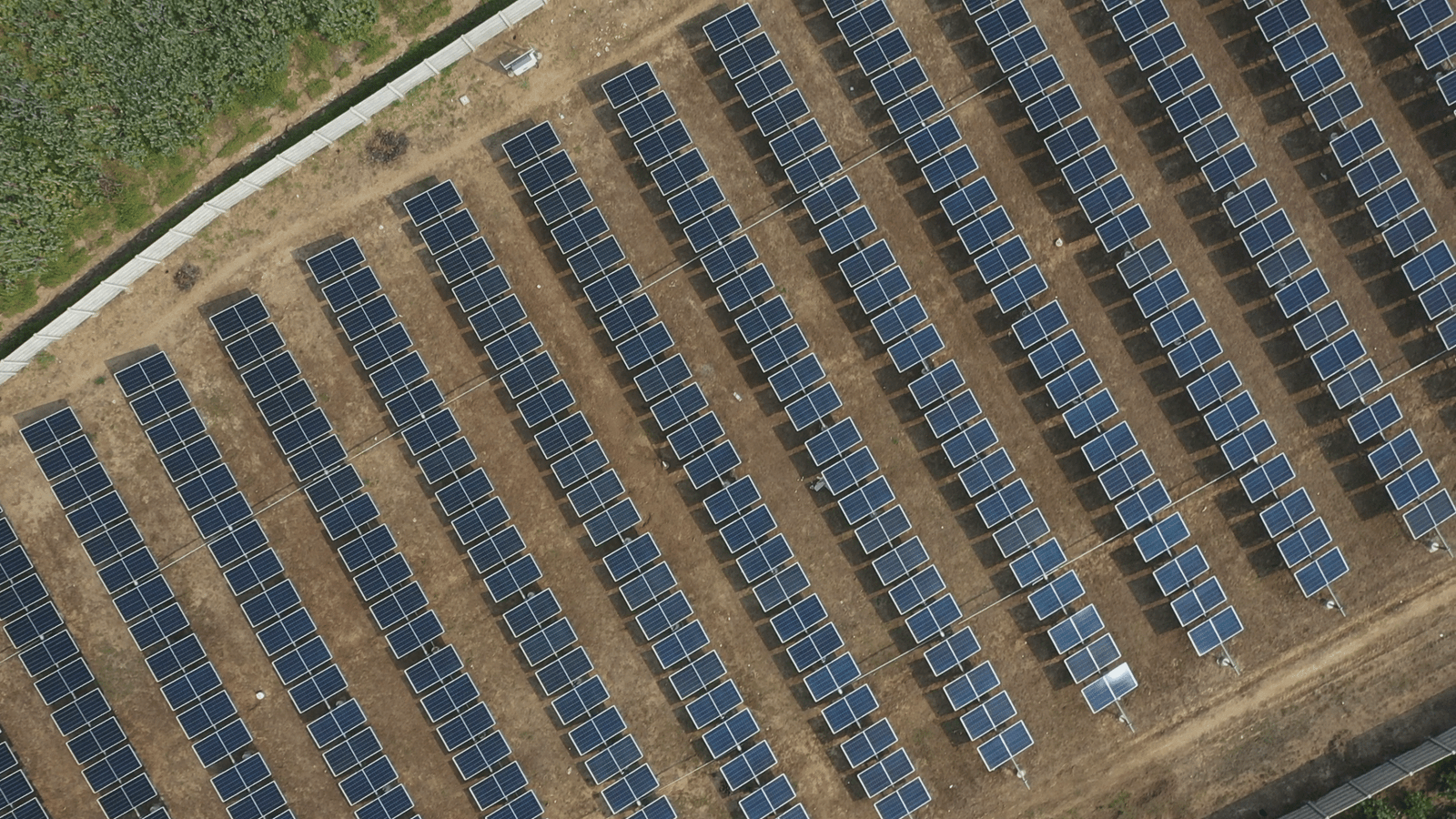

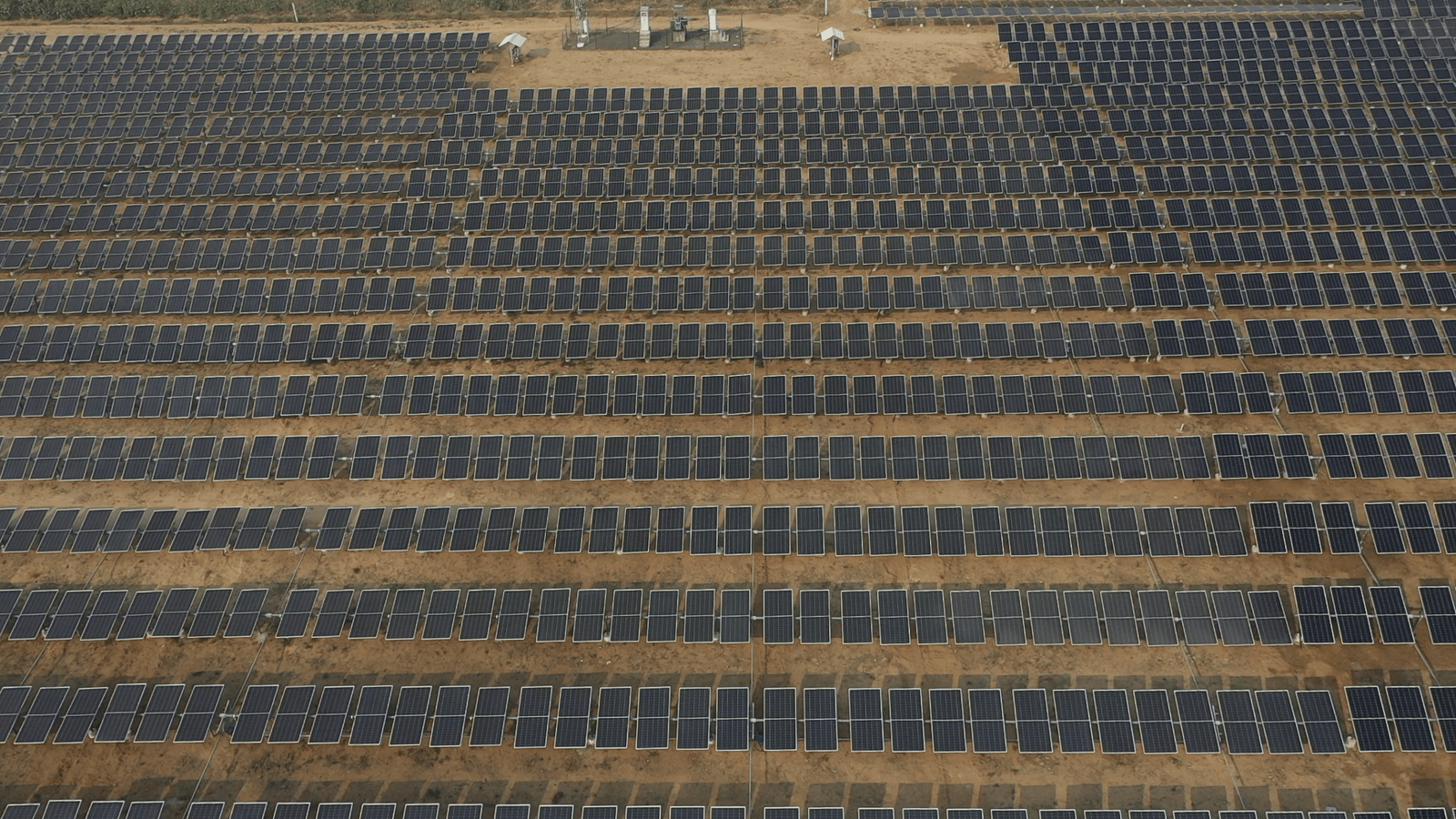

5. Renewable Energy Systems

Remote Terminal Units are essential in renewable energy management by:

- Monitoring performance of solar panels and wind turbines.

- Managing energy storage systems.

- Facilitating grid integration and load balancing.

They ensure efficient operation and maintenance of renewable energy installations.

6. Smart City Infrastructure

In urban settings, Remote Terminal Unit support smart city initiatives through:

- Managing traffic signals and street lighting.

- Monitoring environmental conditions like air quality.

- Enhancing public safety systems.

Their deployment contributes to improved urban living standards and resource management.

9. Advantages of Remote Terminal Units

1. Remote Monitoring and Control

A Remote Terminal Unit enables real-time data acquisition and control of field devices from distant locations. This capability is crucial for industries like oil and gas, power distribution, and water treatment, where equipment is often spread across vast areas.

2. Low Power Consumption

Designed for energy efficiency, a Remote Terminal Unit consumes less power compared to other control devices. They can operate on various voltage levels and are often powered by batteries or solar panels, making them ideal for sites with limited power availability.

3. Rugged and Durable Design

A Remote Terminal Unit is built to withstand harsh environmental conditions, including extreme temperatures and electromagnetic interference. Their robust construction ensures reliable operation in remote and challenging locations.

4. Versatile Communication Capabilities

Supporting a range of communication protocols such as Modbus, DNP3, and IEC 61850, a Remote Terminal Unit facilitates seamless integration with various SCADA systems and field devices. They can communicate over wired or wireless networks, enhancing flexibility in system design.

5. Scalability and Flexibility

A Remote Terminal Unit offers modular configurations, allowing for easy expansion and customization to meet specific application requirements. Their adaptability makes them suitable for diverse industrial processes and system architectures.

10. Challenges in RTU Deployment

Deploying Remote Terminal Unit (RTUs) in industrial and utility settings offers numerous benefits, but it also presents several challenges that organizations must address to ensure successful implementation and operation. Here are some key challenges associated with RTU deployment:

1. Integration with Legacy Systems

Many facilities operate with legacy systems that may not be compatible with modern RTUs. Integrating new RTUs with existing infrastructure can be complex, requiring custom interfaces or protocol converters to ensure seamless communication between devices.

2. Cybersecurity Concerns

As RTUs become more connected, they are increasingly vulnerable to cyber threats. Ensuring the security of RTUs involves implementing robust authentication mechanisms, encrypting data transmissions, and regularly updating firmware to protect against potential attacks.

3. Environmental Challenges

RTUs are often deployed in harsh environments, such as extreme temperatures, high humidity, or areas with significant electromagnetic interference. Designing RTUs that can withstand these conditions is essential to maintain reliable operation over time.

4. Power Supply Limitations

In remote locations, providing a stable power supply to RTUs can be challenging. Solutions may include using solar panels, batteries, or energy-harvesting technologies to ensure continuous operation without frequent maintenance.

5. Complex Configuration and Maintenance

Setting up and maintaining RTUs requires specialized knowledge. Incorrect configurations can lead to data inaccuracies or communication failures. Regular maintenance and updates are necessary to keep RTUs functioning correctly, which can be resource-intensive.

6. Data Management and Bandwidth Constraints

RTUs collect and transmit large volumes of data. Managing this data efficiently and ensuring that communication networks can handle the bandwidth requirements is crucial to prevent data loss or delays in decision-making processes.

7. Scalability Issues

As operations grow, the RTU network must scale accordingly. Ensuring that the system can accommodate additional RTUs without significant reconfiguration or performance degradation is a key consideration during the initial design phase.

11. Future of Remote Terminal Units

1. Enhancing Grid Integration with RTUs

As renewable energy sources like solar power become more prevalent, integrating them into existing grids poses challenges due to their intermittent nature. RTUs play a crucial role in smart grid systems by providing real-time data on energy generation and consumption, enabling better load management and grid stability. Soleos Solar’s expertise in solar EPC and its focus on smart grid solutions underscore the importance of RTUs in modern energy infrastructure

2. Advancements in Communication Technologies

The adoption of advanced communication protocols is enhancing the capabilities of RTUs. Wireless communication technologies, such as LTE and 5G, are enabling more flexible and cost-effective deployments, especially in remote or challenging environments. These advancements allow for faster data transmission and improved system responsiveness.

3. Emphasis on Cybersecurity

As RTUs become more connected, ensuring their cybersecurity is paramount. The increasing threat landscape necessitates the implementation of robust security measures, including encryption, secure authentication, and regular software updates, to protect critical infrastructure from cyber threats.

4. Miniaturization and Cost Reduction

Advancements in technology are leading to the miniaturization of RTUs, making them more compact and cost-effective. This trend allows for broader deployment across various industries, including water treatment, oil and gas, and agriculture, where space and budget constraints are often considerations.

5. Enhanced Data Analytics and Edge Computing

Modern RTUs are incorporating edge computing capabilities, enabling data processing closer to the source. This reduces latency and bandwidth requirements, allowing for real-time analytics and quicker decision-making. Edge computing also supports predictive maintenance by analyzing data trends to anticipate equipment failures before they occur.

6. Standardization and Interoperability

The push towards standardization is facilitating greater interoperability among RTUs and other components within industrial control systems. Adherence to international standards ensures seamless integration and communication between devices from different manufacturers, promoting system efficiency and scalability.

7. Growth in Emerging Markets

Emerging economies are increasingly adopting RTUs as part of their infrastructure development. The need for efficient resource management and the expansion of industrial activities are driving the demand for RTUs in regions such as Asia-Pacific, Latin America, and Africa.

8. Integration with Renewable Energy Sources

RTUs are playing a crucial role in the integration of renewable energy sources into the grid. They enable the monitoring and control of distributed energy resources, such as solar panels and wind turbines, ensuring stable and efficient energy production and distribution.

9. Focus on Sustainability

There is a growing emphasis on the environmental impact of RTU operations. Manufacturers are designing RTUs with energy-efficient components and materials, and implementing practices that minimize environmental footprints, aligning with global sustainability goals.

10. Artificial Intelligence and Machine Learning Integration

The incorporation of AI and machine learning into RTUs is enhancing their functionality. These technologies enable RTUs to learn from data patterns, optimize operations autonomously, and improve system performance over time, leading to smarter and more efficient control systems

12. Conclusion

The future of Remote Terminal Unit (RTUs) is marked by significant growth and technological advancements, driven by the increasing need for efficient monitoring and control systems across various industries . Remote terminal unit are evolving to meet the growing demands of modern industries. With advancements in communication technologies, integration with smart grids, and enhanced data analytics capabilities, remote terminal unit are becoming more intelligent and adaptable. As industries continue to embrace digital transformation, remote terminal unit will play a pivotal role in enabling efficient, secure, and sustainable operations across various sectors.