Electric power systems are the backbone of modern infrastructure, from industrial plants to residential grids. To ensure safety and efficiency, it’s vital to have reliable switching and protection devices. One such highly efficient and advanced protective device is the VCB (Vacuum Circuit Breaker). Known for its robust design, minimal maintenance needs, and superior performance, VCBs are increasingly becoming the standard in medium-voltage switchgear solutions.

Table of Contents

In this comprehensive guide, we’ll explore everything you need to know about VCB (Vacuum Circuit Breaker)—how it works, its components, advantages, types, applications, and why it is the preferred choice in modern power systems.

What is VCB (Vacuum Circuit Breaker)?

A Vacuum Circuit Breaker (VCB) is an electrical switchgear device designed to protect electrical systems by interrupting current flow during abnormal conditions, such as short circuits or overloads. It utilizes a vacuum as the arc-quenching medium, making it particularly effective for medium-voltage applications ranging from 11 kV to 33 kV.

How Does a Vacuum Circuit Breaker Work?

When a fault occurs in the electrical system, the VCB‘s contacts separate, and an arc forms due to the ionization of metal vapors. However, the vacuum environment quickly extinguishes this arc because:

- High Dielectric Strength: Vacuum has superior insulating properties, preventing sustained arc formation.

- Rapid Recovery: The dielectric strength in a vacuum recovers swiftly, allowing the interrupter to regain its insulating capability almost immediately after arc extinction.

This rapid arc quenching minimizes damage to equipment and ensures the safety of the electrical system.

Working Principle of VCB (Vacuum Circuit Breaker)

The primary principle behind the operation of a VCB (Vacuum Circuit Breaker) is arc quenching in vacuum. Here’s a step-by-step breakdown:

- Normal Operation: Under standard conditions, the VCB’s fixed and moving contacts remain closed, allowing uninterrupted current flow through the circuit.

- Fault Detection: When an abnormal condition like a short circuit or overload occurs, protective relays detect the fault and signal the VCB to operate.

- Contact Separation and Arc Formation: The actuator mechanism responds by separating the moving contact from the fixed contact within the vacuum interrupter. This separation causes an arc due to the ionization of metal vapors emitted from the contacts.

- Arc Quenching in Vacuum: The vacuum environment, maintained at pressures typically between 10⁻⁶ to 10⁻⁴ torr, provides a medium with high dielectric strength. In this environment, the arc is quickly extinguished as the metal vapors, electrons, and ions rapidly condense on the contact surfaces, restoring insulation properties almost instantaneously.

- Current Interruption: The rapid recovery of dielectric strength in the vacuum ensures that the arc does not re-establish, effectively interrupting the current flow and isolating the faulty section of the circuit.

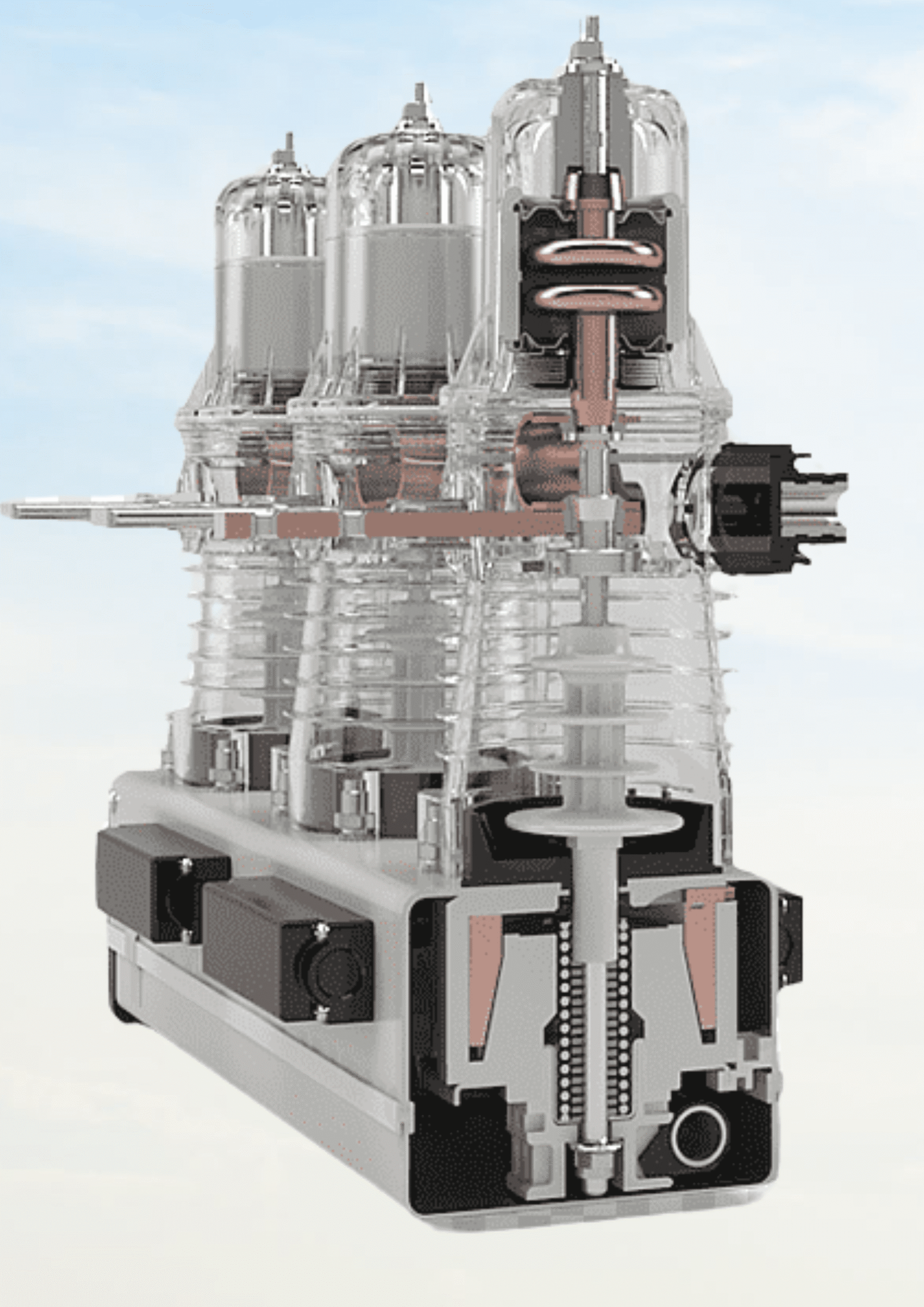

Components of a VCB (Vacuum Circuit Breaker)

- Vacuum Interrupter: The core component where arc interruption occurs. It consists of fixed and moving contacts enclosed in a vacuum-sealed chamber. When contacts separate, the vacuum extinguishes the arc quickly.

- Fixed and Moving Contacts: Conductive elements that open and close to interrupt or allow current flow. The moving contact operates via an external mechanism, while the fixed contact remains stationary.

- Arc Shield (Main and End Shields): These shields absorb metal vapor during arc formation, preventing it from contaminating the vacuum envelope and ensuring uniform electric field distribution.

- Bellows: A flexible, airtight component that allows the moving contact to operate while maintaining the vacuum seal within the interrupter.

- Operating Mechanism: This mechanism facilitates the opening and closing of contacts, either manually or automatically. It can be spring-operated or motor-driven, depending on the design.

- Insulating Enclosure: Typically made of materials like epoxy resin or porcelain, this enclosure provides mechanical strength and electrical insulation, safeguarding internal components from environmental factors.

- Support Insulators: These provide structural support and electrical insulation for the interrupter and other components within the VCB.

- Mechanism Linkage: Connects the operating mechanism to the moving contact, ensuring synchronized operation during opening and closing actions.

- Glass Fiber Rod: Used in some designs to provide additional insulation and mechanical support within the breaker pole.

- Opening Spring: Provides the necessary force to open the contacts swiftly during fault conditions, ensuring rapid arc extinction.

Types of VCB (Vacuum Circuit Breaker)

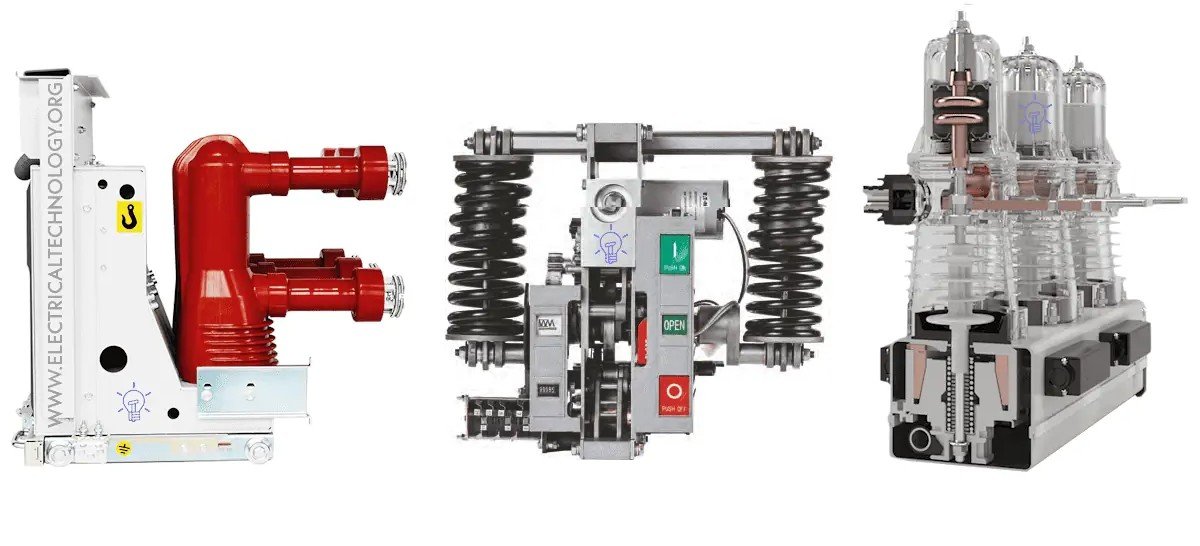

VCBs come in various configurations based on voltage ratings, application type, and installation design. The common types include:

1. Outdoor VCB

- These weather-resistant pole-mounted or weatherproof enclosures are designed for harsh outdoor environments, suitable for power distribution networks, rural electrification, and utility substations. They offer a long service life, minimal corrosion risk, and are ideal for installations where weather conditions are unavoidable, making them ideal for outdoor use.

2. Indoor VCB

- These VCBs are ideal for indoor installations in industrial plants, manufacturing units, commercial buildings, and substations. They are compact, space-saving, and provide protection from environmental elements. They also offer easy maintenance access. They are suitable for medium-voltage applications where space efficiency and protection from external conditions are crucial.

3. High Voltage (HV) Vacuum Circuit Breakers

- This document describes a high-voltage power transmission system used for handling voltages above 36 kV, ensuring reliability and safety in transmission-level systems. It highlights its features such as high interrupting capacity, reliable operation in complex grid systems, and enhanced dielectric performance, making it essential for managing large-scale power distribution.

4. Hybrid Vacuum Circuit Breakers

- This document describes a vacuum interrupter that optimizes performance by combining vacuum technology with other arc-quenching mediums like SF₆ gas. It is suitable for complex power systems, high-speed switching, and minimal energy loss, making it versatile, efficient, and suitable for critical load centers. It also reduces dielectric recovery time.

Each type of VCB (Vacuum Circuit Breaker) has its own set of advantages and is chosen based on the application and operational needs.

Advantages of VCB (Vacuum Circuit Breaker)

The VCB (Vacuum Circuit Breaker) offers several key advantages over traditional circuit breakers:

1. High Interrupting Capacity

- VCBs can efficiently interrupt high fault currents, ensuring the protection of electrical equipment and maintaining system stability.

2. Low Maintenance Requirements

- VCBs feature sealed vacuum interrupters that do not degrade over time, reducing the need for frequent inspections and servicing. They are sealed for life, unlike oil or SF₆ circuit breakers, making them ideal for facilities aiming to reduce operational downtime.

3. Environmentally Friendly

- VCBs are a sustainable alternative to traditional circuit breakers due to their lack of SF₆ gas, a potent greenhouse gas, and their zero emissions, ensuring no risk of gas leaks or environmental contamination.

4. Compact Design

- VCBs are lightweight and compact, making them ideal for urban and commercial setups in small switchgear compartments, facilitating easy installation and integration into existing systems, making them ideal for space-efficient use.

5. Quiet Operation

- Vacuum arc interruption (VCB) is a quiet and clean alternative to air blast or oil circuit breakers, making it ideal for commercial buildings, hospitals, and research facilities, eliminating the need for noise reduction measures.

6. Suitable for Frequent Operation

- VCBs can handle frequent circuit switching without significant degradation, making them ideal for applications requiring regular operations.

These benefits make VCB (Vacuum Circuit Breaker) an ideal solution for modern electrical systems.

Applications of VCB (Vacuum Circuit Breaker)

VCB (Vacuum Circuit Breaker) technology is widely used across various sectors, including:

1. Industrial Plants

- VCBs are crucial in industrial facilities for protecting electrical equipment like motors, transformers, capacitor banks, and generators due to their ability to handle high load currents and frequent operations. They are ideal for heavy-duty environments like manufacturing units, steel plants, chemical factories, and cement industries, as they protect machinery from electrical faults and resist corrosive environments. VCBs also safeguard motor control centers.

2. Power Generation Stations

- VCBs are essential in office complexes, hospitals, shopping malls, IT parks, and data centers for uninterrupted power supply and protection against electrical faults. They offer silent, low-maintenance, and highly reliable protection, minimizing downtime and protecting sensitive electrical loads, making them crucial for medium-voltage distribution.

3. Commercial Buildings

- VCBs are essential in office complexes, hospitals, shopping malls, IT parks, and data centers for uninterrupted power supply and protection against electrical faults. They offer silent, low-maintenance, and highly reliable protection, minimizing downtime and protecting sensitive electrical loads, making them crucial for medium-voltage distribution.

4. Utility and Grid Infrastructure

- VCBs are essential in office complexes, hospitals, shopping malls, IT parks, and data centers for uninterrupted power supply and protection against electrical faults. They offer silent, low-maintenance, and highly reliable protection, minimizing downtime and protecting sensitive electrical loads, making them crucial for medium-voltage distribution.

5. Railway Electrification Systems

- VCBs are utilized in railway switchyards, substations, metro systems, and rapid transit networks for managing and protecting overhead electrification systems, due to their quick fault-clearing ability and compact design.

The adaptability of the VCB (Vacuum Circuit Breaker) to a range of environments makes it a universal choice in today’s power sector.

VCB vs Other Circuit Breakers

| Feature | VCB (Vacuum Circuit Breaker) | ACB (Air Circuit Breaker) | SF₆ Circuit Breaker | Oil Circuit Breaker |

|---|---|---|---|---|

| Arc Quenching Medium | Vacuum | Air | Sulfur Hexafluoride (SF₆) gas | Mineral oil |

| Voltage Range | Medium voltage (up to 38kV) | Low voltage (up to 1kV) | High voltage (up to 800kV) | Medium to high voltage |

| Arc Extinction Speed | Very fast (within milliseconds) | Moderate | Fast | Moderate |

| Maintenance | Low (sealed system, minimal wear) | Moderate (dust and carbon cleaning needed) | Requires gas handling and leak checks | High (oil degradation and carbon cleaning) |

| Size and Weight | Compact and lightweight | Bulky in size | Compact in GIS (Gas Insulated Systems) | Large and heavy |

| Environmental Impact | Eco-friendly (no emissions) | No harmful emissions | SF₆ is a potent greenhouse gas | Risk of oil spills and fire hazards |

| Interrupting Capacity | High | Moderate | Very high | High |

| Installation Preference | Indoor/Outdoor substations, switchgear | Commercial buildings, panel boards | High-voltage substations, GIS systems | Older substations (now being phased out) |

| Cost | Moderate upfront, low operational | Low upfront, moderate maintenance | High cost due to gas management | High due to oil maintenance and safety systems |

| Lifespan | Long (20+ years with minimal maintenance) | Moderate (frequent checks required) | Long, but depends on gas system integrity | Shorter due to oil maintenance demands |

Clearly, VCB (Vacuum Circuit Breaker) holds an edge in performance, safety, and eco-friendliness.

Maintenance of VCB (Vacuum Circuit Breaker)

- Record-Keeping and Monitoring to track test results, contact wear levels, replaced components, and maintenance date and nature.

- Regular visual inspection to detect signs of wear, overheating, corrosion, or mechanical misalignment.

- Check for external damage, oil deposits, cracks, arc exposure, and contact wear or erosion.

- If contact erosion exceeds manufacturer’s allowable limit, the interrupter must be replaced.

- Periodic electrical testing to evaluate internal health and performance.

- Lubrication of moving parts annually with manufacturer-approved grease to prevent dust accumulation and jamming.

- Vacuum Integrity Test to maintain vacuum level below specified pressure.

- Functional Operation Test to ensure correct operation of manual opening/closing cycles, trip coil actuation test, interlocking system validation, and auxiliary contacts operation.

Future of VCB (Vacuum Circuit Breaker)

The Vacuum Circuit Breakers (VCBs) market is expected to grow at a CAGR of 7.9% from 2025 to 2034, reaching a valuation of USD 13 billion by 2034. Key trends include their integration with smart grid technologies, such as IoT, which enhances grid reliability and operational efficiency. Advancements in materials science, particularly nanotechnology, are contributing to the development of more durable VCBs, capable of handling higher voltages and currents.

Environmental sustainability is another driving factor, as VCBs operate in a vacuum, making them more environmentally friendly. The Asia-Pacific market is expected to witness the highest growth in VCB adoption, driven by rapid urbanization, infrastructure development, and investments in renewable energy projects. These developments position VCBs as a critical component in modernizing global power systems, ensuring reliable, efficient, and eco-friendly electrical infrastructure.

Conclusion

Vacuum Circuit Breakers (VCBs) are revolutionizing medium-voltage power systems with their unmatched safety, reliability, and low maintenance needs. From industrial plants to commercial hubs, VCBs offer a clean, efficient, and future-ready solution to electrical protection. As the demand for sustainable and smart energy infrastructure grows, VCBs are becoming the preferred choice across the globe.

Ready to Power Up with VCB Technology? At Soleos Solar, we don’t just provide solar solutions — we power progress. Whether you’re upgrading your facility’s electrical infrastructure or planning a greenfield solar project, our expert team can help you integrate advanced VCB systems for optimal performance and safety. Connect with us today for a customized consultation and discover how VCBs can enhance your energy reliability and efficiency.

FAQs About VCB (Vacuum Circuit Breaker)

1. What is a VCB (Vacuum Circuit Breaker)?

A VCB is a type of circuit breaker that uses a vacuum to extinguish the arc formed when electrical contacts open. It’s highly reliable and widely used for medium-voltage power systems.

2. How does a Vacuum Circuit Breaker work?

When a fault occurs, the VCB separates its contacts. The arc that forms is quickly extinguished in the vacuum due to the absence of ionized particles, ensuring safe and rapid interruption.

3. What are the main advantages of VCB?

- Low maintenance

- High reliability

- Fast arc quenching

- Eco-friendly (SF₆-free)

- Long service life

4. Where are VCBs commonly used?

They are widely used in:

- Industrial power distribution

- Commercial buildings

- Power generation plants

- Substations

- Railway traction systems

5. How often should VCBs be maintained?

VCBs require very minimal maintenance. However, a routine check-up every 12 to 24 months is recommended depending on usage.

6. How can you detect a vacuum failure in VCB?

A high-voltage withstand test can reveal a loss of vacuum. If the vacuum is compromised, the test will show insulation failure or a flashover.

7. What voltage levels are VCBs suitable for?

VCBs are ideal for medium-voltage applications, typically ranging from 3.3 kV to 33 kV systems.

8. Are VCBs safe to use?

Yes, VCBs are very safe. They emit no toxic gases, have minimal risk of fire, and their sealed design prevents contamination.

9. How long does a VCB last?

A typical VCB can operate for 10,000 to 30,000 cycles depending on the model and conditions, making it a long-lasting solution.

10. Can VCBs replace older types of breakers?

Yes, VCBs are a modern replacement for oil and air circuit breakers due to their superior performance and safety features.